News

The benevolent breaking of bones

How are implants made intelligent? Two specialists from the research project on smart implants—mechatronics engineer Dr Paul Motzki from the Center for Mechatronics and Automation Technology in Saarbrücken and mathematician Dr Michael Roland from the Professorship for Engineering Mechanics at Saarland University—share their insights.

Have you ever broken a bone?

Paul Motzki: Yes, I once broke my femur in a sports accident. It was fixed with two rods in the side of my thigh—it looked pretty gruesome. Fortunately, the fracture healed well, but I know from other cases among my family and friends that difficulties can arise. My brother had problems for more than two years after breaking his collarbone, and a friend who broke his humerus in a moped accident in Thailand also needed additional treatment for quite some time. So I’m familiar with the fact that fractures don’t always heal without complications.

Now you want to make intelligent implants that support the healing process. How are you developing these?

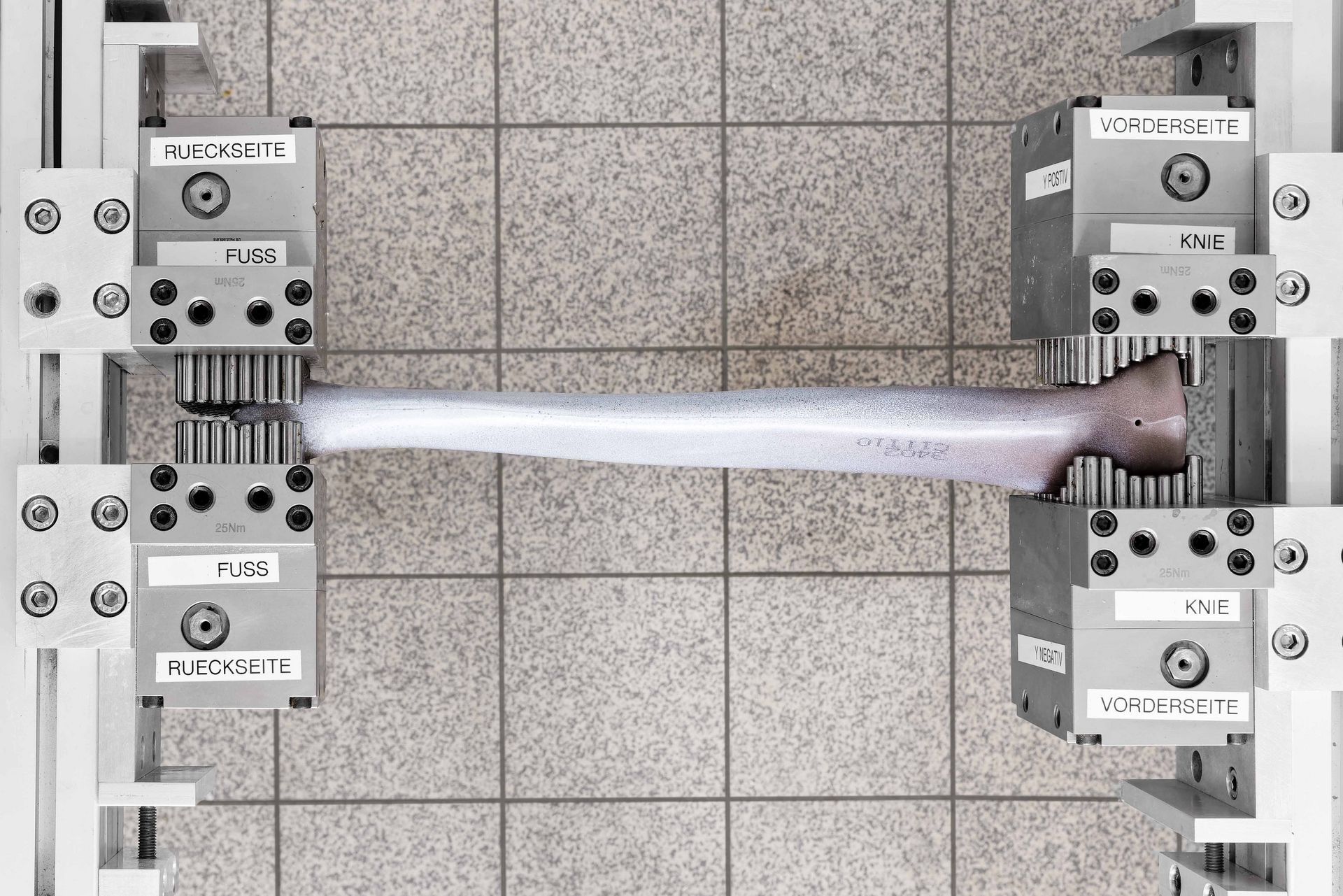

Michael Roland: First of all, we need data, data and more data, because it’s crucial that we understand exactly which forces are acting on the bone. There has been research on animals in this area, but practically none involving humans. Right now, the physicians in our team are collecting data from test persons wearing shoes with smart insoles. We use this data to simulate the relevant forces and observe their effect in experiments. We’ve developed two machines for this. With the first device, we press and twist the bones until they break. Then we clamp them in the second unit, where we let the measured forces act on the bone. This enables us to see how the fracture and the bone are affected. The measure-ments help us to identify various factors, such as how stiff the bone still is, and we use a camera system to observe how the fracture moves. Then we pass on the test results to the mechatronic engineers.

What do the mechatronic engineers do with the results?

Motzki: We use the data to test the materials that we plan to use in producing, or rather modifying the implant to make it “smart”. Right now, we’re testing around the clock to observe the fatigue behaviour of the materials. In other words, we want to find out how the materials change when they’re subjected to the wear and tear of millions of test cycles or when we change the ambient conditions such as temperature and humidity.

How do you go about making the implant intelligent?

Motzki: Our idea is to coat a standard plate with modular material layers that have sensoric properties, enabling precise measurement of the forces acting upon the fracture. In addition, the implant should also perform actuator functions—in other words, it must be able to directly steer the healing process by translating the signals from the sensors into a movement or change of form. We want to use novel materials to implement this function, too.

What exactly are these new intelligent materials?

Motzki: They’re special metals that warp under thermal activation, but can “remember” their original state. They have very good sensoric properties. We’re experimenting at the moment with a nickel-titanium combination, a so-called shape-memory alloy. Most people are familiar with these from flexible eyeglasses, orthodontic wires—or, in medicine, stents. The technology is well researched, and attempts have already been made to combine it with new materials to achieve a better actuator function. Our work builds on this research.

What are the greatest challenges in producing smart implants?

Roland: Although we’re making good progress with the simulations, it will probably be most difficult to determine the key factors steering the healing of fractures. When does a break heal well? What causes complications to arise? For this, we need a great deal of data, also from patients who experience complications. These data are central: our simulations are based on them, as are the algorithms developed by our colleagues at the German Research Center for Artificial Intelligence.

Motzki: On the technical side, the actuator function presents the greatest challenge. But I’m fairly optimistic on this front, as the materials and the technology are in principle well known and available. Rather than creating a new material, we need to prepare existing materials for use in medical applications, and we have considerable expertise in this area. Another clear challenge is coordinating the various disciplines. We’re dependent on one another because we need good data from our project partners. We also have to be sure that we’re speaking the same language.

Can you give an example?

Motzki: Sometimes we use the same words to mean different things, which can lead to misunderstandings. For example, once the physicians were talking of “shearing movements”. They were referring to movements of patients that are suboptimal for the healing process, as they can cause the fracture surface to shift sideways. We’re familiar with the notion of “shear force” from engineering, but didn’t know what that had to do with fractures. So for a while we were at cross purposes. The fact that our facilities in Saarland are close together and we can meet easily is certainly an advantage. Our communication is frequent and very productive.

Aynur Gökten, research nurse at the Department of Trauma, Hand and Reconstructive Surgery, Saarland University Medical Center

Kerstin Wickert, Professorship for Engineering Mechanics, Saarland University

Prof. Dr Tim Pohlemann, project initiator and director of the Department of Trauma, Hand and Reconstructive Surgery, Saarland University Medical Center

Dr Tim Dahmen, German Research Center for Artificial Intelligence, Saarbrücken

PD Dr Marcel Orth, Department of Trauma, Hand and Reconstructive Surgery, Saarland University Medical Center

Annchristin Uhl, graduate student at the Professorship for Engineering Mechanics, Saarland University

Dr Michael Roland, Professorship for Engineering Mechanics, Saarland University

Are there also differences in mentality between researchers from the different fields?

Motzki: The disciplines are really very different. We engineers are trained for precision: every millimetre counts; we always seek ideal solutions and strive for innovation. Medicine, and surgery in particular, are more empirical disciplines, and physicians generally take a more conservative approach, as their priority is minimising patient risk. And sometimes on-the-spot decisions are necessary for the benefit of the patient.

Roland: Physicians often don’t have time to wait for the ideal solution, and patient health is dependent on a variety of factors. One thing I’ve learned is that it can be better to operate on a broken bone quickly rather than waiting and observing, because otherwise the risk of infection increases. In the end, it’s the physician’s responsibility to find a good solution for each patient. For me as a mathematician, the inter-disciplinary teamwork has been greatly rewarding.

Interview: Andres Eberhard

Photos: Oliver Lang