News

Thermoelectrics, ultra-fast

Testing materials for their capacity to efficiently convert temperature differences into electricity is a complex, time-consuming process. That’s why Maria Ibáñez and her team at IST Austria are looking forward to the day that their new high-throughput unit is in operation.

Novel materials are the essence of physicist Maria Ibáñez’s work. But fabricating new materials requires not only profound knowledge—a great deal of time and patience are also necessary. As are the right tools. It often takes numerous attempts before a material presents the right properties, and when researchers have to make every new mixture by hand in their lab and then test it individually, progress is painfully slow.

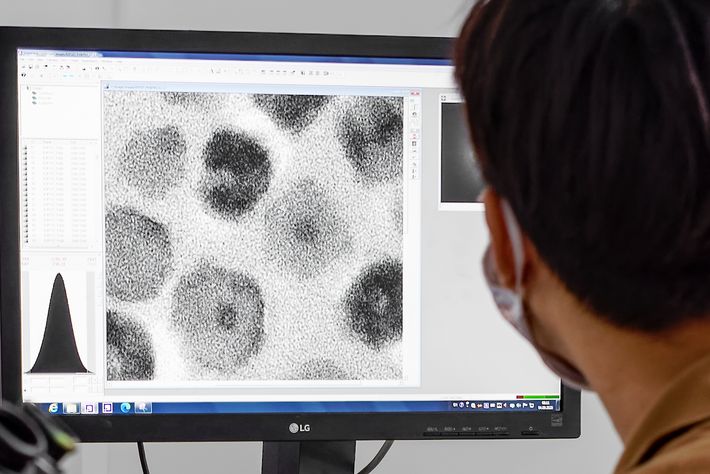

The materials that Ibáñez and her team are developing have precisely defined nanostructures. The researchers grow polycrystals of a thermoelectric material—tin selenide, for example—in an aqueous solution and then coat the surface with the molecular complexes of a second material, for instance cadmium selenide. “To test this kind of new material system by hand and also vary the different parameters, a researcher would need eight months, even a year,” Ibáñez says.

This is what makes her all the more excited about the high-throughput infrastructure currently being built in her new lab. To be sure, there have been several delays due to supply shortages and because it was difficult to hire specialised engineers during the coronavirus pandemic. “But now we’re working on a prototype.” The new unit is capable of fabricating material combinations and testing them at the same time. Ibáñez hopes that the prototype will be in operation by spring 2023. The finished equipment, which has several other functions, should be ready for general use a few months later. “That’s my big goal for the year,” Ibáñez says.

High-performance polycrystals

Despite the pandemic-related delays, Ibáñez is satisfied with her group’s progress, saying, “We’ve now laid the cornerstones for our work and have decided which methods we’ll use to test which materials in the high-throughput lab.” The team have recently published a number of promising findings in top-tier journals. One article discussed their development of a new way to fabricate tin selenide using a polycrystalline structure that is more cost-effective to produce; the resulting thermoelectric performance is on a par with the best materials in the—costly—single crystal form.

In another important development, Ibáñez says the team “can now control how big the grains in the crystals grow, which in turn affects the grain boundaries”. The boundaries are the decisive factor in how heat is transported. In future, the researchers will be able to use them for optimising the thermoelectric performance of their mater-ials. And this new knowledge can also be applied to improve polycrystalline materials, Ibáñez adds. “Solar cells are one example.”