Six innovative ideas win a WSS research prize

The Werner Siemens Foundation (WSS) has announced the finalists in its “project of the century” ideas competition: six innovative projects from Germany and Switzerland have been awarded a WSS research prize of one million Swiss francs. In December, one of the finalists will be selected as the overall winner and receive a ten-year grant of one hundred million Swiss francs to set up a WSS Research Centre for the sustainable use of the planet’s resources.

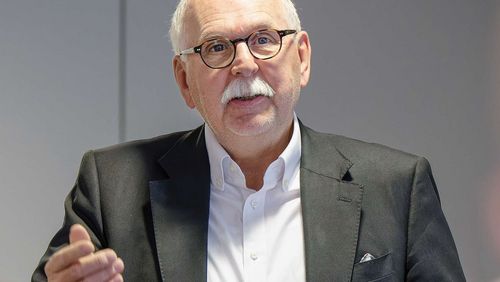

On the occasion of its 100th anniversary, the Werner Siemens Foundation launched an ideas competition for a WSS Research Centre dedicated to researching and developing technologies for the sustainable use of natural resources. The call for proposals generated an enormous echo, with 123 almost exclusively first-rate researchers from Germany, Austria and Switzerland submitting their ideas to the Foundation’s office in Zug, Switzerland. “We were very impressed with the quality, variety and future-oriented outlook of the ideas as well as with the researchers’ enthusiasm, their optimism and courage to take risks,” says Professor Matthias Kleiner, long-serving member of the Scientific Advisory Board of the Werner Siemens Foundation and former president of the German Research Foundation and Leibniz Association.

Innovative technologies

The WSS Scientific Advisory Board reviewed the submissions in consultation with a team of experts experienced in the assessment of research projects. A recommendation was then sent to the Foundation Board and the Siemens Family Advisory Board, who selected six ideas and awarded each project team a WSS research prize of one million Swiss francs. The winning projects were submitted by researchers in Germany and Switzerland who explore topics ranging from sustainable chemical processes on to solar hydrogen production, efficient photovoltaic systems and highly controlled food production.

The award ceremony will take place on 16 June 2023 in Lucerne. The prize winners now have until the end of October 2023 to draw up a detailed proposal for their vision of a WSS Research Centre for the Sustainable Use of Resources. The final decision will be announced in December 2023.

Project of the century

The WSS Research Centre will be endowed with a total of one hundred million Swiss francs over a ten-year period. It’s the largest project ever financed by the Werner Siemens Foundation, whose philanthropic mission is offering generous funding to long-term research projects. “We wanted to mark our anniversary by launching an exceptional, far-reaching project,” says Dr Hubert Keiber, Chair of the Foundation Board of the Werner Siemens Foundation. “And the project ultimately selected for the WSS Research Centre will most certainly help to better protect natural resources and foster sustainability.”

Indeed, the Werner Siemens Foundation sees the ideas competition as an opportunity to actively promote sustainable use of our planet’s resources. Energy, air, water, food, habitats and raw materials are all limited natural goods that should be used and managed with great care. Science can—and must—do its part.

> ChemSysCon: New Chemical Systems for the Conversion of Sustainable Resources

> catalaix: Catalysis for a Circular Economy

> Revolution of Food Production

> Fuels and Commodities out of Thin Air

> Highly Efficient Generation of Electricity and Hydrogen from Solar Energy

> RenewSusCat: Renewable Energy for Sustainable Catalysis

ChemSysCon: New Chemical Systems for the Conversion of Sustainable Resources

Chlorine—one of the most important commodity chemicals—plays a major role in the synthesis of more than half of all commercial products in the chemical industry, and no other chemical element has such a great impact on our daily lives. However, industrial chlorine production is extremely energy intensive: the roughly 5.5 million metric tons of chlorine produced every year in Germany account for more than two percent of the country’s overall electric power consumption. Moreover, chlorine gas is toxic, and today’s storage and transport methods come with high risks, despite numerous regulations. A research team led by Sebastian Hasenstab-Riedel at Freie Universität Berlin have found a solution to this problem by developing an extremely cost-effective chemical chlorine reservoir that, in a low-energy process, binds chlorine gas in an ionic liquid, making it safe and easy to handle the gas even when it is airborne.

The team at Freie Universität Berlin, the German Bundesanstalt für Materialforschung und -prüfung (BAM) and the Fraunhofer Institute for Applied Polymer Research (IAP) now want to further develop their technology and prepare it for market entry. One advantage of their innovation is that it would promote better use of renewable energies in chlorine manufacturing processes. For example, chlorine could be produced in nations with particularly high solar radiation and then shipped to other countries. In addition, their chlorine-based ionic liquid could also be used in the chemical treatment of waste materials. In their vision for a future WSS Research Centre, the researchers propose using their novel ionic liquid as well as other kinds of ionic liquids to break down biowaste like lignin, a by-product of the manufacture of paper that at present is generally burned. In future, however, it could be recycled into new commodity chemicals based on renewable raw materials. The researchers also have another potential application in mind: recycling electronic scrap materials with the aim of recovering valuable precious metals or rare earth elements.

Project leader

Prof. Dr Sebastian Hasenstab-Riedel

Managing director of the Institute of Chemistry and Biochemistry

Freie Universität Berlin

catalaix: Catalysis for a Circular Economy

Packaging, insulation materials, textiles, fertilisers, pharmaceutical products: it’s difficult to imagine modern life without the products created in the chemical industry. Unfortunately, however, most of these products are thrown away at the end of their life cycle. Researchers in the groups of Jürgen Klankermayer and Regina Palkovits at the Rhein-Westphalian Technical University Aachen want to ensure that these kinds of waste streams can be converted into valuable, reusable resources—in short, they want to create integrated systems from linear value chains. To achieve their aim, they plan on developing tailor-made catalytic systems and integrating renewable sources of raw materials and energy into the recycling process. The team’s flexible and targeted approach makes it possible to convert what was once a residual product into valuable raw materials for the chemical industry, hence into new products.

The development of a value creation cycle for the plastics market is one example of their vision for a future WSS Research Centre. Between 2000 and 2019, a mere nine percent of plastic produced worldwide was recycled, a statistic that has motivated the researchers to find a way to convert materials made of plastic into reusable raw materials by means of a combined chemical, electrochemical and microbial procedure. They’ve already demonstrated that their approach works for diverse classifications of plastics.

However, the researchers’ idea goes beyond individual, isolated cycles of matter. They want to expand production cycles in line with an open-loop principle, meaning that the molecular building blocks—the starting materials generated through recycling—can be made to measure and used in so many different ways that they could be fed into other value chains and material cycles as needed. This procedure creates the basis for a flexible, multidimensional circular economy that will help bring about the sustainable transformation of the chemical industry.

Project leaders

Prof. Dr Jürgen Klankermayer

Chair of Translational Molecular Catalysis

RWTH Aachen University

Prof. Dr Regina Palkovits

Chair of Heterogeneous Catalysis and Technical Chemistry

RWTH Aachen University

Revolution of Food Production

How can we feed the world’s growing population without depleting natural resources like water and soils, and thus destroying ecosystems? Answering this question is the research focus of Senthold Asseng and his team at the Technical University of Munich. Their approach centres on ways to produce food in a controlled environment—in short, a radical expansion of the vertical farming systems that already exist. To realise their innovative idea, the scientists breed plants that are adapted to the controlled conditions in which light, temperature, humidity, ventilation, water and fertilisers are meticulously monitored. Because the system eliminates weeds, pests and diseases, the use of pesticides is superfluous. In earlier studies, the researchers have already shown that the yield of crops—wheat, for example—grown in vertically stacked layers could be up to six-hundred times higher, as the procedure allows for several harvests per year.

Should they win the ten-year grant to establish a WSS Research Centre, the researchers plan to develop this type of system using wheat as a pilot crop. Wheat is the source of one-fifth of all calories consumed by humans, and it has also been extensively studied. For the Centre, the team would fully re-optimise the crop for the controlled conditions of vertical farming, where the plants are less susceptible to disease than in conventional farming and their root systems need less energy to grow. On the basis of models and simulations, the researchers will be able to predict which conditions promote fastest growth. Thanks to the highly efficient circulation systems, vertical farms use ninety-nine percent less water and sixty percent less fertilisers. After ten years, the team also plan to develop a pilot system consisting of ten large vertically stacked crop layers. This would mean a reduction in the area required for growing crops, thus freeing up land currently used for intensive farming for re-naturalisation.

Project leader

Prof. Dr Senthold Asseng

Director of the Hans Eisenmann-Forum for Agricultural Sciences

Technical University of Munich

Fuels and Commodities out of Thin Air

Hydrogen is widely regarded as the energy carrier of the future—but only if there’s a way to produce it without burning fossil fuels. The most elegant method would be using the sun’s energy to split water into hydrogen and oxygen molecules. A research team led by Greta Patzke and David Tilley at the University of Zurich want to develop precisely this principle of solar hydrogen production and prepare it for market entry. The researchers have been studying the potential of solar hydrogen production for quite some time and have already made excellent progress towards realising their novel solar particulate panel (SPP) reactors. In particular, the team developed various catalysts to greatly accelerate water splitting and make it more efficient. Studies suggest that solar hydrogen production via semiconductor catalysts is already as economically viable as hydrogen that is produced using fossil fuels.

If their project wins the competition for a WSS Research Centre, the team will continue to research and develop SPP reactors on the basis of various catalysts. Within ten years, they plan to have demo reactors in place that cover more than 100 square meters. But the conversion efficiency of these plants isn’t the only important factor: the panels must be durable, and the catalysts produced using cost-effective, environmentally friendly and commonly occurring materials as far as possible. Ecological quality, long-term safety and sustainability of the technology are therefore all integral parts of the project. In the long term, however, the SPP reactors should be able to do much more than generate eco-friendly hydrogen. The researchers say their technology will make it possible to produce basic chemicals, convert carbon dioxide into affordable liquid fuels and sustainably manufacture fertiliser from nitrogen. It would be a step towards revolutionary materials that can be easily produced anywhere, without causing harm to the environment.

Project leaders

Prof. Dr Greta R. Patzke

Department of Chemistry

University of Zurich

Prof. Dr David Tilley

Department of Chemistry

University of Zurich

Highly Efficient Generation of Electricity and Hydrogen from Solar Energy

Solar energy is booming, but today’s solar cells made of crystalline silicon have an efficiency of less than thirty percent. Moreover, a great deal of energy is required to manufacture them, with most of it stemming from climate-unfriendly coal-fired power plants in China, the market leader in photovoltaics. A team of researchers led by Frank Dimroth and Andreas Bett from the Fraunhofer Institute for Solar Energy Systems (ISE) and the Albert Ludwig University of Freiburg want to realise a more efficient, cost-effective and resource-conserving technology—in short: a breakthrough in this area. Their project explores so-called III-V tandem photovoltaics, which are solar cells consisting of several semiconductor layers made up of elements from the third and fifth groups of the periodic table. These tandem solar cells are very efficient and are capable of withstanding high temperatures. In addition, the researchers have developed a method to separate the semiconductor layers—with a width of just a few micrometres—from the substrate. This means they can be reused several times for growing new solar cells. The procedure saves material and costs, and it represents a particularly sustainable way to generate solar power.

Combining the III-V semiconductor tandem solar cells with high-concentration photovoltaics (CPV) technology is particularly promising. In this process, economic lenses are used to amplify the sunlight by a factor of one thousand before a tiny solar cell converts it into electricity. This saves more than seventy-five percent of the energy needed to produce a silicon module. Moreover, CPV modules remain stable for long periods of time and can be recycled easily. Dimroth, Bett and their teams have recently manufactured a solar cell that attains efficiency levels of 47.6 percent with highly concentrated sunlight (665-fold intensity)—a world record. Their idea for a WSS Research Centre is to make this technology easier to produce and even more efficient, cost-effective and environmentally sustainable. They also want to research and develop methods for converting seawater into ecological hydrogen using their solar-energy technology.

Project leaders

Dr Frank Dimroth

Head of the Department for III-V Photovoltaics and Concentrator Technology

Fraunhofer Institute for Solar Energy Systems ISE Freiburg

Prof. Dr Andreas Bett

Institute of Physics, University of Freiburg

Director of the Fraunhofer Institute for Solar Energy Systems ISE Freiburg

RenewSusCat: Renewable Energy for Sustainable Catalysis

Fertilisers, fuels and medications all have one thing in common: producing them generally requires a great deal of energy—energy stemming from fossil resources and suitable catalysts for accelerating reactions. On one hand, a shift from oil and gas to renewable energy sources is needed to make the chemical industry sustainable; on the other, new catalytic systems are also necessary. As far as possible, these systems should be based on elements that are non-toxic, widespread and easily accessible. Researchers in the team led by Lutz Ackermann at the University of Göttingen want to tap into the potential of sustainable catalysis. Their main goal is utilising wind and solar power to generate new molecules via reactions in which the sole by-product is hydrogen. The hydrogen can then be used as a sustainable energy carrier. As a further advantage: linking these two processes makes this type of novel catalytic system extremely marketable.

In their vision for a WSS Research Centre, the researchers draw on diverse strategies to develop sustainable chemical processes, including different types of catalysts such as electro- and photo-electrocatalysts, catalysts powered by renewable energies as well as types based on commonly occurring metals. With some strategies, it’s even possible to modify and diversify highly complex molecules at the last moment, so to speak. This capacity drastically shortens synthesis procedures, thereby also preventing unwanted by-products from forming, as the researchers have already demonstrated with pharmaceutical products. Last but not least, chemists need new methods to quickly predict which new syntheses are safe and environmentally responsible. To make this possible, the researchers are working with software applications that use machine learning to evaluate chemical reactions.

Project leader

Prof. Dr Lutz Ackermann

Wöhler Research Institute for Sustainable Chemistry

Institute of Organic and Biomolecular Chemistry

Georg-August-Universität Göttingen