A muscle near to the heart

Heartening prospects for patients with cardiac insufficiency: a ring around the aorta that helps the heart to pump blood through the body. This state-of-the-art technology is the research focus at the Center for Artificial Muscles in Neuchâtel—and is funded by the Werner Siemens Foundation.

Shortness of breath, low energy, feeling exhausted: the hearts in patients with cardiac insufficiency—the medical term for a weak heart—are quite literally too tired to circulate enough blood through the body. In Switzerland, cardiac insufficiency affects up to 200 000 individuals, mainly older people. Diseased coronary arteries are generally what weakens the cardiac muscle (myocardium). Put briefly, these hearts need more muscle power—and making weak hearts stronger is one of the research aims of the new Center for Artificial Muscles (CAM) in Neuchâtel. The centre, which is part of the Swiss Federal Institute of Technology Lausanne (EPFL), was opened at the start of 2018 and is financed by the Werner Siemens Foundation.

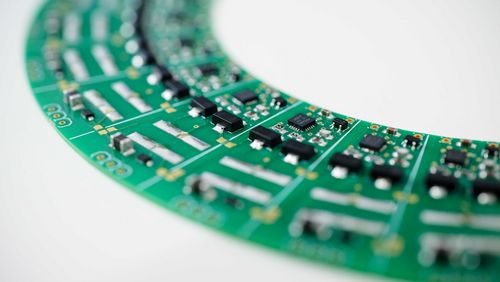

A researcher with experience

Professor Yves Perriard is director of the Center for Artificial Muscles, and the 53-year-old microengineer has chosen a research topic close to his heart in the truest sense: several years ago, he had to undergo heart surgery to correct a defective valve. And since his doctoral studies, Yves Perriard has conducted research into technical systems that support heart function, including Ventricular Assist Devices (VAD), which range from simple pumps to actual artificial hearts. As such, Perriard is well aware of the serious drawbacks of current technologies: pumps have to be inserted into the heart and come in contact with the blood, thus increasing the risk of infection and thromboses. Now, the 10-member team at CAM is pursuing an entirely novel approach to helping people with cardiac insufficiency. The ambitious goal? Creating artificial muscles that support the pumping capacity of the myocardium. The microengineers are currently working on an elastic membrane that can be placed around the aorta as a ring with a diameter of roughly 2.5 centimetres. An electrical impulse then causes the ring to dilate and contract, thus pumping blood through the body. The great advantage is that the operation needed to place the artificial ring around the aorta is less invasive than actual heart surgery. Another plus is that the ring never comes into contact with the blood.

The heart—a mighty muscle

“The biggest challenge is generating the necessary pumping capacity,” says CAM director Yves Perriard. “After all, the heart is a strong muscle.” The ring must be able to achieve a capacity of one watt to pump over 7000 litres of blood through the circulatory system every day. To increase the performance of the elastic ring, the researchers have integrated into the system a titanium spring that was developed by a Neuchâtel company especially for the project, patent pending. The spring supplies additional mechanical stress to ensure that the ring can exert the requisite pressure on the artery; it is possible that several rings will have to be placed around the aorta to attain the targeted pumping capacity. The demands placed on the artificial muscle are exacting. For example, the ring has to be extremely elastic, powerful and must not trigger any rejection mechanisms in the body, meaning it must be biocompatible. What material has all these qualities? Perriard and his team hit on the answer with electroactive polymers, which are a type of synthetics.

Huge capacity required

The challenge facing the research team lies in developing a new, specific polymer able to achieve the necessary capacity of one watt. What chemical properties will it have? How thick should it be? To find answers, the team under Perriard and CAM general manager Yoan Civet is currently creating

a variety of membranes in a clean room. The researchers then subject the membranes to several tests: for instance, the ring for the aorta must be able to withstand a voltage ranging from 3000 to 5000 volts or even more. And, yes, this is much more than the 220-volt current in a standard European outlet. But not to worry: the artificial muscle will have full electrical insulation and therefore pose no danger to the patients.

Electricity thanks to magnetic induction

To transfer the electrical power, no wiring will be necessary. The electrical power will originate in a 12- or 24-volt battery placed outside the patient’s body—for instance on a belt—and be transferred via magnetic induction: a coil is electrically charged to create a magnetic field, and the power is then transferred to a second coil that is placed inside the body. This is the principle behind wireless charging of the newest generation of mobile phones, and the same technology will be used to ensure that the aorta ring receives an adequate supply of energy. But the ring’s sole purpose is not just pumping blood through the body; it should also function as a sensor. The researchers envision that the polymer will measure various factors such as blood pressure in the aorta, adjust the pressure on the artery accordingly and also synchronise the pumping action with the patient’s heartbeat.

Precision technology from the Jura region

These are ambitious goals, and Yves Perriard is the right man for the job. In 2003, Perriard was named director of the Integrated Actuators Laboratory (LAI) at the School of Microengineering at EPFL. The lab is specialised in transforming electrical energy into mechanical motions—researchers have dubbed these minuscule motors “actuators”. In the past, the team’s research has not been restricted to systems for supporting cardiac capacity but has also branched out into other medical applications such as insulin pumps and surgical instruments. The Center for Artificial Muscles did not establish its domicile in Neuchâtel by chance. “In the Jura region, you don’t have to tell anyone what a micrometre is,” Perriard says with a laugh, adding that precision work down to a thousandth of a millimetre has a long tradition here—in the watch-making industry. Today, the same precision is demanded at research institutions and in the bio- and nanotechnology companies now located in the region. One of the hubs for such activities is the so-called “Microcity”. Situated in the heart of the capital of Neuchâtel, Microcity is home to researchers and various companies, including start-ups—and Yves Perriard and his research team have also taken up quarters there.

Mounting anticipation in Bern

Forty kilometres south-east of Neuchâtel, one person in particular is paying close attention to the developments at the Center for Artificial Muscles: Thierry Carrel, renowned heart surgeon and director of the Department of Cardiovascular Surgery at Inselspital Bern. Starting in 2022, Carrel will test the aorta ring in clinical trials (see interview). Until then, the new technology will be studied using a silicon model of an aorta and in animal testing. Dominik Obrist, professor for Biofluid Mechanics and Cardiovascular Engineering at the University of Bern, is in charge of this part of the project.

Artificial sphincters

Ultimately, the artificial muscles created in the Neuchâtel lab should be able to do more than just help weak hearts. In particular, the research team aims to develop an artificial muscle suitable for a wide range of applications in various parts of the human body. This would indeed be a major medical advancement: although prostheses for bones and joints have been established in medicine for quite some time, artificial muscles have remained elusive. From 2018 to 2029, the Werner Siemens Foundation is supporting this groundbreaking research. During the

funding period, the team at CAM will also develop two other applications for the artificial muscle. The first is an artificial sphincter for the urinary bladder to help patients suffering from urinary incontinence regain control over their bladders.

Facial expressions

The second application for the artificial muscle is to restore chewing function and facial expressions to accident and burn patients. In such cases, the artificial muscle will not have the shape of a ring, but that of a small, flat membrane. The researchers in this sub-project anticipate a particularly great challenge because—especially in the face—it is advantageous to connect the artificial muscle to the patient’s nerve tissue, thus ensuring that the resulting muscle movements are as natural as possible. To achieve this goal, Yves Perriard is collaborating with Professor Nicole Lindenblatt from the Department of Plastic Surgery and Hand Surgery at University Hospital Zurich. Indeed, it becomes clear that developing artificial muscles requires an extraordinarily multidisciplinary team of specialists from fields as diverse as microengineering, materials science, biomedicine and surgery.

A world’s first

The first goal, however, is enabling patients with cardiac insufficiency to benefit from the innovative research conducted at CAM. A system to support heart function in the form of a ring around the aorta—that would be an absolute first in the world of medicine. And with Yves Perriard and Thierry Carrel, a practiced team is tackling the challenge: the two researchers have engaged in professional exchange since their first encounter at Inselspital Bern—10 years ago, when Thierry Carrel successfully operated on Yves Perriard’s heart.

Text: Adrian Ritter

Photos: Felix Wey

Illustration: bigfish