The perfect biorefinery

Thomas Brück and his team at the Werner Siemens Foundation Endowed Chair have developed several designs for a biorefinery able to convert biomass into chemical and pharmaceutical building blocks. But this isn’t Brück’s only goal.

What's your greatest dream?

Thomas Brück: My greatest dream is a single bioreactor that’s able to produce diverse products neatly separated from each other.

What would this bioreactor look like?

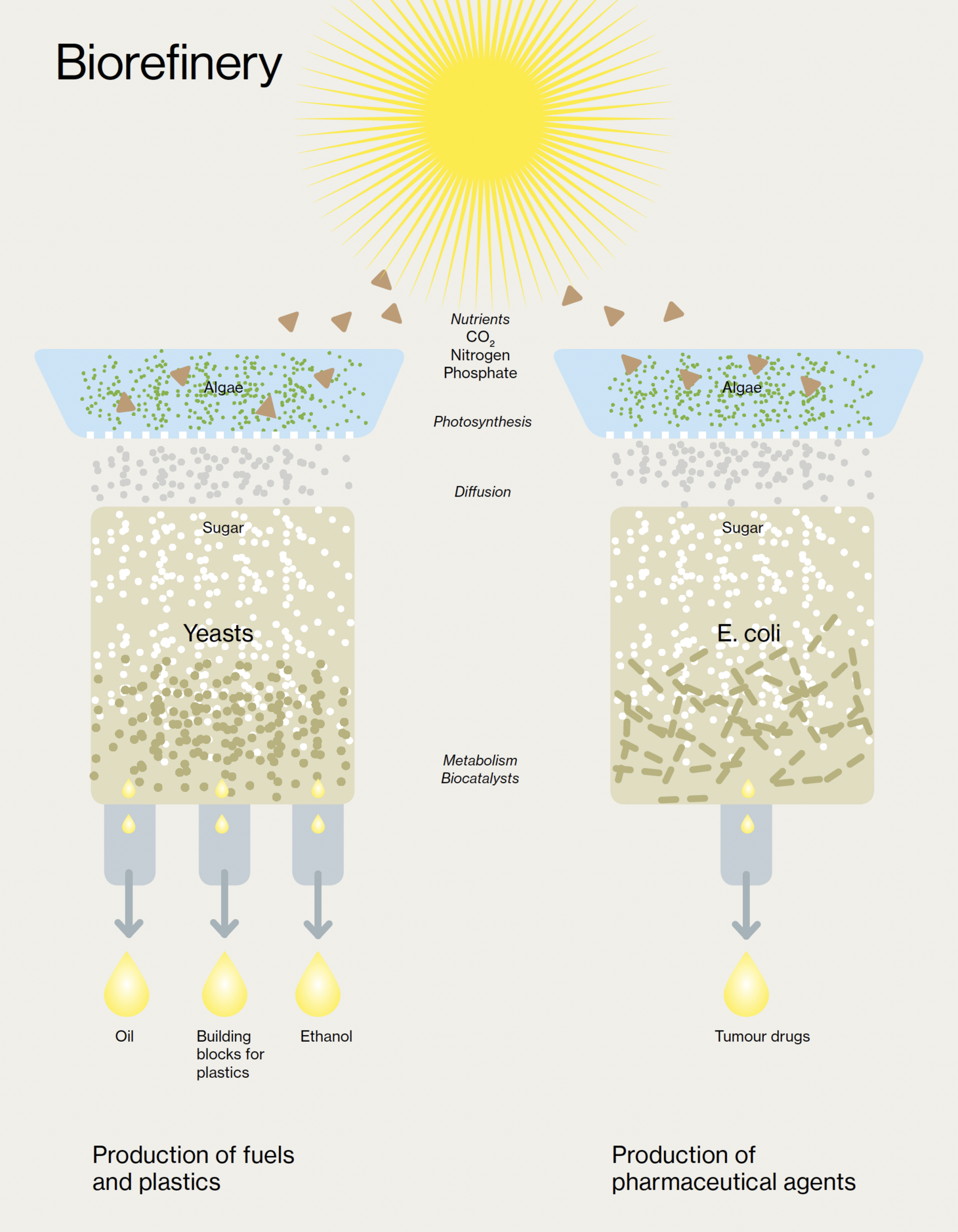

It would be a large, multi-part bioreactor from a 3-D printer. The top compartment would be for algae that produce sugar via solar light, carbon dioxide, nitrogen and phosphate. The sugar could then be diffused into the next compartment and be used, for example, to feed fatty yeast. The fatty yeast would release the fats and oils it produces into the surrounding area. The oils would then flow through little tubes into yet another compartment. This is how we’d also like to produce the cancer drug Taxol: for example, by using tailor-made gut bacteria E. coli in the middle compartment.

What would be the advantage over today’s methods?

The big challenge today is getting bioorganisms to release their metabolic product. It takes quite a bit of work before we can harvest the product in its pure form. An organismic bioreactor would render these complex and expensive processing steps entirely obsolete because the end product would flow into special channels. The bioreactor we have in mind is modelled on human organs—for instance, the kidneys.

Interview: Brigitt Blöchlinger

Photos: Felix Wey