Sending the earth’s crust for an MRI

Studying geological structures on-site poses major logistical challenges. And so, ETH Zurich professor Martin Saar has decided to move the mountain to the lab: in his latest project to receive funding from the Werner Siemens Foundation, he plans to recreate geological reservoirs with a 3D printer at a much smaller scale and then use a custom-made MRI device to observe how gases, liquids and rocks interact deep below the earth’s surface.

We need clean energy. And we need new strategies to get to grips with the concentration of greenhouse gas in the atmosphere. The solution to both issues may be located right under our feet: not only can carbon emissions from fossil fuels be stored in many of the earth’s formations or in former gas and oil deposits—the earth also harbours unfathomable quantities of sustainable energy, as a cubic section of the earth’s crust with an edge length of just ten kilometres contains enough heat energy to cover the annual energy demand of the world’s entire population.

However, tapping into these geothermal energy reservoirs is no simple matter. Drilling is expensive, as the heat has to be extracted from several kilometres below the surface. What’s more, we still don’t fully understand many of the processes occurring in the earth’s interior. Indeed, the chemical, physical and biological properties of an underground layer have been formed over the course of millions of years. “When we inject, store and extract fluids like water, CO2, crude oil or natural gas, we trigger various changes and disturb the natural chemical and thermodynamic balance,” explains Martin Saar, geophysicist and Werner Siemens Foundation Endowed Chair of the Geothermal Energy and Geofluids (GEG) group at ETH Zurich.

For instance, chemical reactions can cause mineral precipitation and rock weathering, which in turn can block or open up new flow paths for heat or reactant transport. These altered pathways then exert an influence on the fluid itself, potentially causing more rock minerals to weather or precipitate. “We’re dealing with highly complex feedback mechanisms,” Martin Saar explains. Over time, these processes can have serious ramifications on operations, for example concerning geothermal energy extraction and utilisation or subsurface CO2, hydrogen and methane storage. For this reason, investigating reactive transport—the chemical interactions between porous rock and the medium flowing through it—is of major importance and one of the priorities in Saar’s research group.

Making flow pathways visible

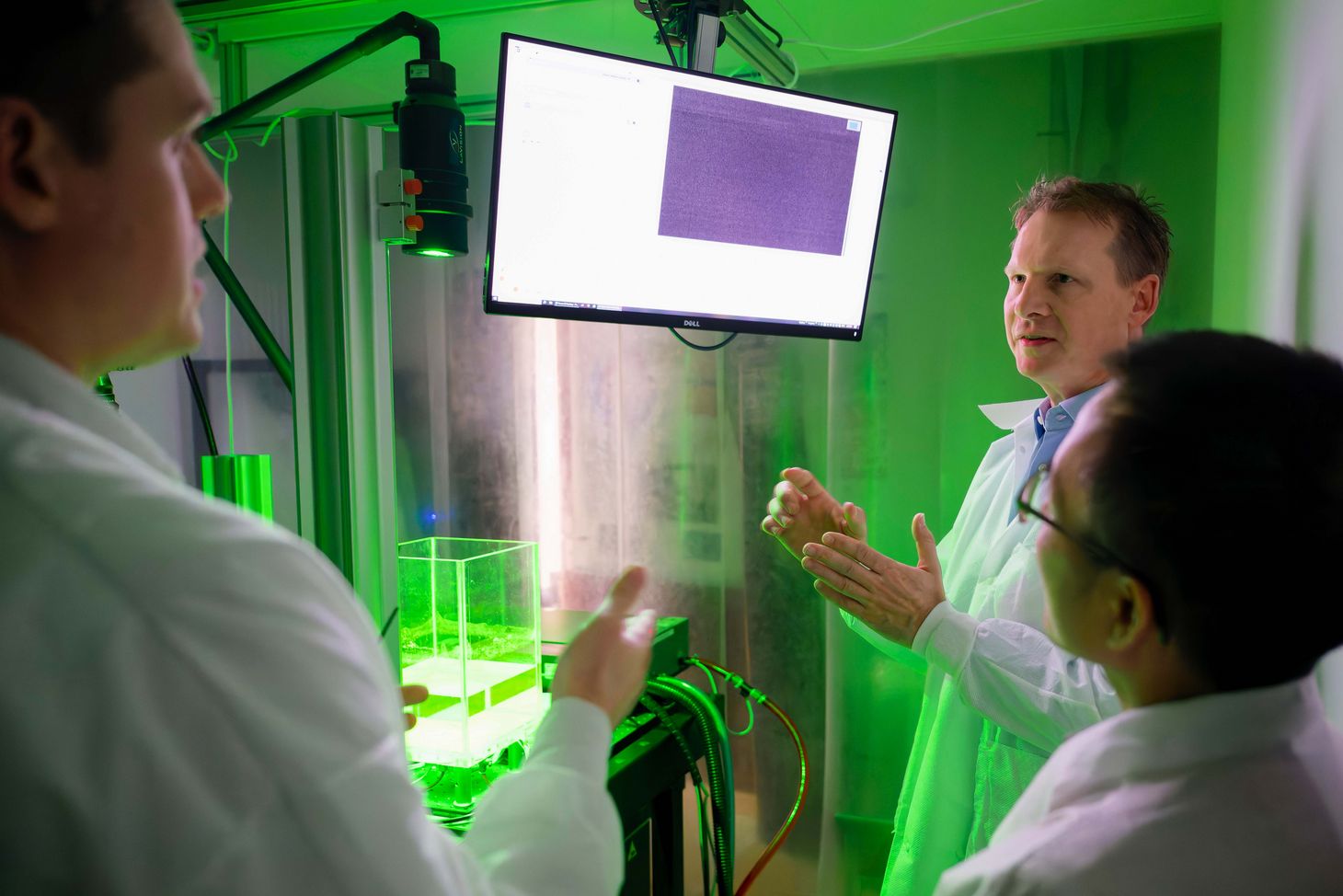

In the field of geology, computer simulations are often used to investigate thermal (T), hydraulic (H), rock-mechanical (M), chemical (C) and biological (B) processes and to better understand their complex interactions. The development and application of these numerical simulations also play a key role for the GEG group at ETH Zurich. However, because the complex feedback effects occurring during these so-called THMCB processes are not yet fully understood, computer simulations alone are an inadequate research tool. Thus, THMCB experiments in the lab are indispensable, as they contribute to developing and calibrating the computer programs.

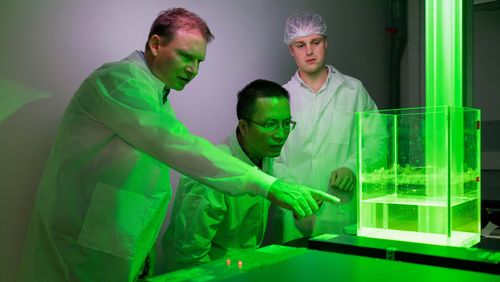

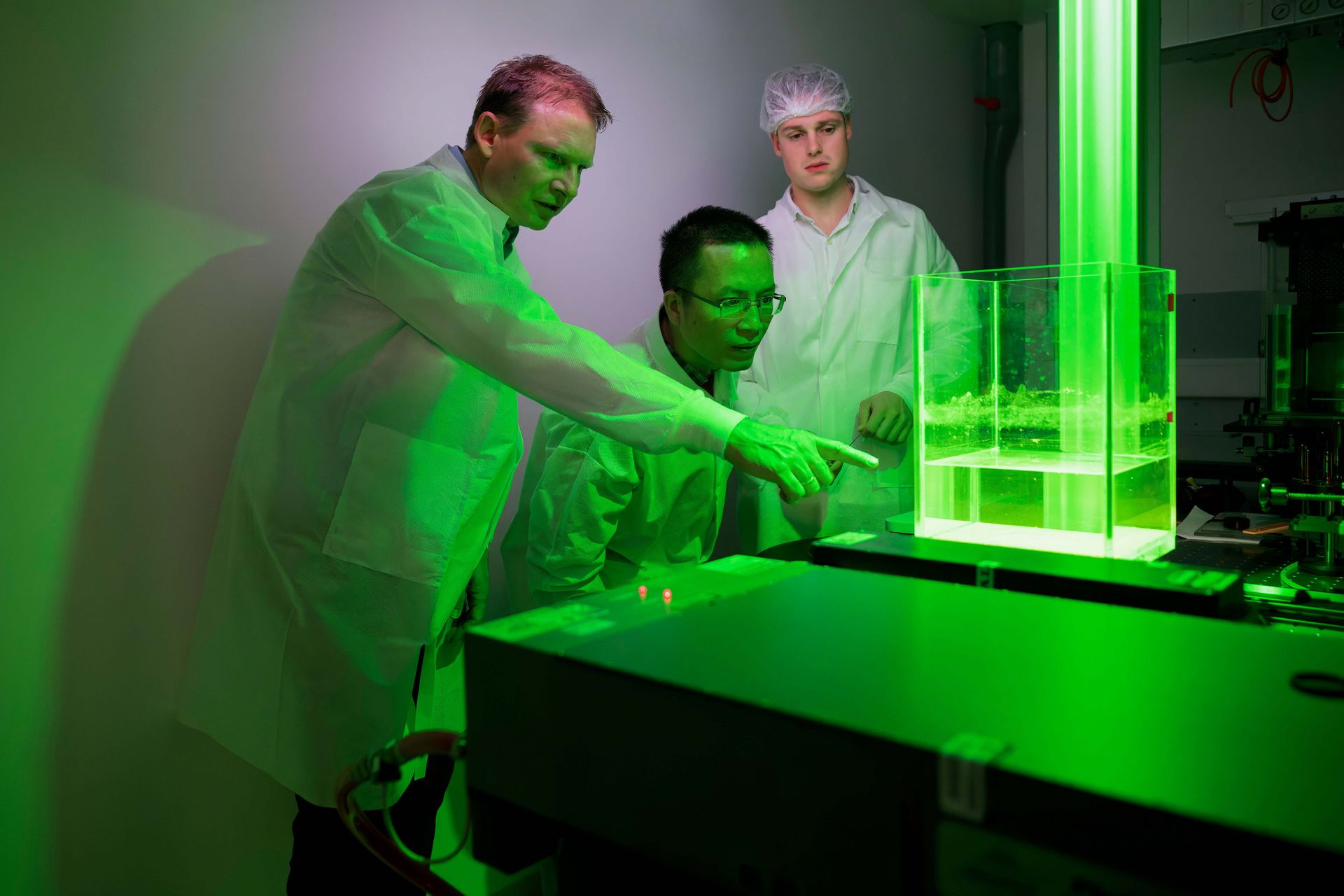

In the past, Saar and his team have often conducted these lab tests using computed tomography (CT scans) in the group’s own CT scanner. “We expose rock to a specified pressure and temperature, inject a fluid, and then observe in real time where the rock begins to weather, where minerals precipitate, and how fluid and energy flow paths change as a result,” Saar explains. “The problem with CT technology is that we can almost only observe how the porous medium, the rock, changes, but we can hardly see the flow behaviour of the various liquids and gases—the CO2 that we add to groundwater or brine for permanent CO2 sequestration to combat climate change, for example.”

This is set to change, thanks to Saar’s new research endeavour, which has recently been awarded a ten-year grant of fifteen million Swiss francs from the Werner Siemens Foundation. The centrepiece of the project is a custom-made multi-nuclide magnetic resonance imaging (MRI) device that will likely be the only one of its kind. MRIs are generally used in medical care and, compared to CT scans, the great advantage of MRI imaging is the ability to create visual renderings of different fluid types—those found in body tissue, for example. Put simply, the MRI forms a magnetic field to excite the nuclei in certain atoms, causing them to vibrate; these vibrations then generate a signal that is measured and processed, enabling distinctions between different kinds of fluids or materials to be made.

Most commonly, MRIs target the hydrogen atom (H-1), because the human body consists mostly of water. However, MRIs have also been used to examine isotopes such as carbon C-13, fluorine-19 (F-19), sodium-23 (Na-23) and xenon-123 (Xe-123). “I asked myself whether we could use an MRI to visualise and distinguish between water, hydrogen gas (H2), brine, carbon dioxide, methane and fluorine-labelled microbes when they move through porous rock, potentially all at the same time,” Martin Saar explains. He discussed his idea with several highly respected MRI experts, who confirmed that the multi-nuclide MRI technique should also work in reactive transport experiments on porous rock materials that are exposed to high-pressure and high-temperature conditions without damaging the device. What’s more, it’s also possible to determine the temperature and pressure field with MRI scans—and all that in three dimensions (3D) and varying over time (4D). “The individual components we need have already been developed, but not yet in the combination necessary for our purposes,” Saar says. And adds that, to his knowledge, the specific new GEG MRI and its capabilities to house high-pressure and high-temperature experiments would be a world’s first.

Preparatory work

Saar and his team now plan to conduct tests with existing MRI devices to learn more about the technical specifications the new equipment would need to meet for their planned experiments. One particular challenge is ensuring that the highly sensitive magnetic coils built into MRIs are protected from extreme heat. After all, in order to replicate the geological conditions acting in the first five kilometres of the earth’s crust, the test rock must be exposed to temperatures of up to 200 degrees Celsius and a pressure of about 500 bar. Saar says one of their ideas is to use so-called aerogels for thermal insulation, as even thin layers of these ultralight silica structures provide effective heat protection. Only after the team have identified the requirements for each component of the novel MRI will Saar begin to draft a call for tenders for its construction.

He predicts that the new machine will be standing in his lab in about two years. By then, the second key component for the team’s experiments should also be ready: a 3D printer capable of printing ceramic replicas of rock formations—replete with underground deposits, reservoirs, faults and even fluid injection and production boreholes. The geological formations in miniature will be roughly the size of one or two bricks, yet still contain all important geological and engineered features, as modern 3D printers can produce ultra-thin layers measuring no more than a hundredth of a millimetre.

The custom-made devices will enable Saar’s group to observe processes that unfold deep in the earth’s interior—and will signify a big step forward for their highly promising research projects that have already been funded by WSS for the past ten years. One of these projects is based on a method Saar co-invented and named—CPG (CO2-Plume Geothermal)—which is designed to make the capture and permanent sequestration of carbon dioxide in deep geological reservoirs to mitigate climate change economically viable. The procedure works as follows: when the greenhouse gas CO2 is stored between 2.5 and 5 kilometres below ground, it naturally heats up to at least 100 degrees Celsius. Saar wants to exploit this heat by creating a circuit by which the geothermally heated carbon dioxide is brought back to the land surface where it’s used in turbines to generate electricity—and then channelled back into the underground storage facility so that the CO2 injected at the start is permanently stored deep in the subsurface. Because carbon dioxide is less viscous than water and expands much more when heated, it has a higher heat production rate, enabling more economical extraction of geothermal energy, and even the production of electricity, in less permeable rock layers at relatively low subsurface temperatures.

Saar says the new instruments will also prove useful in this work. Indeed, in addition to studying methods of subsurface carbon storage, they could be used to experimentally simulate in the lab the underground storage of hydrogen, methane and other gases. For such experiments, too, countless variations of geological layers and boreholes could be printed in 3D, and hydrogen or methane then be injected into a miniaturised reservoir that is pressurised and heated in the MRI for 3D-imaging. Here, the main question concerns the conditions at which these gases can be best stored underground and then retrieved to the surface for energy production. Saar explains that answering questions around subsurface gas, in particular hydrogen, storage is of key importance because the mass production of “green” hydrogen expected in future must be met with temporary storage in the subsurface, as the quantity of hydrogen will far exceed the capacity of above-ground storage tanks.

Methane production with microbes

A new project that is particularly near and dear to Saar is a combination of all of the above: developing a sustainable method of underground methane production. The idea is compelling: sustainably produced, meaning without CO2emissions, “green” hydrogen and carbon dioxide are introduced into the subsurface together with specific kinds of microorganisms. Below ground, these tiny organisms utilise the earth’s heat to transform the hydrogen and carbon dioxide molecules into methane, which is now CO2-neutral and stored directly underground. Subsurface storage of methane is an established way to safely store energy. When needed, the CO2-neutral methane generated underground is then conveyed back to the ground surface and used as an energy resource in existing facilities.

However, this “methanogenesis” is a complex process. “We can’t just try something like this out in the field and watch what happens. We first need to conduct detailed lab experiments,” Saar says. He adds that the new MRI would be ideal for such tests, as multiple instances of a geologic reservoir and wells can be 3D-printed and as different H2 and CO2 gas and microbe injection rates and subsurface temperatures and pressures can all be physically tested to calibrate the above-mentioned THMCB computer programs for large, reservoir-scale simulations and eventually field experiments.“We could observe where the CO2, the hydrogen, the microbes and the produced methane go and where they accumulate as well as optimise the placement of injection and production wells. The goal is to have a nearly complete conversion of ‘green’ hydrogen and CO2 to ‘green’ methane, full recovery of the methane via production wells, and keeping any leftover carbon dioxide underground.”

In a next step, the idea is to incorporate data from these experiments when conducting upscaled THMCB computer simulations, which is another core activity of Saar’s GEG group. “The 3D temperature fields, pressure fields and velocity vectors of the various fluids and microbes delivered by the MRI will be like a dream come true when calibrating large-scale THMCB computer simulations,” Saar says. With this combined laboratory and numerical approach, it’s possible to extrapolate how the various underground processes interact over a wide range of spatial and temporal scales in a way that is impossible to recreate when employing laboratory experiments or computer simulations alone.

Conversely, the lab experiments will be useful for consolidating the data collected in the field. “We currently conduct field studies in many places worldwide and will then be able to use these data to create realistic 3D-printed reservoir models,” Saar explains. “However, when we analyse years of measurements made, for example, in an Indonesian geothermal system, it’s impossible to know whether the findings can be generalised to other locations.” But first conducting the downscaled laboratory experiments inside the MRI scanner to calibrate computer codes and then using the calibrated codes to conduct modified numerical THMCB simulations for other sites would enable researchers to determine whether or not a dataset is more widely applicable.

Seeking the origins of life—and other experiments

The new MRI unit is also interesting to researchers outside Saar’s area of specialisation. One example is a collaboration with the ETH Zurich Centre for Origin and Prevalence of Life (COPL) led by astronomer and Nobel laureate Didier Queloz, where researchers are interested in understanding where and how carbon and microbes accumulate in rock layers and in identifying the temperatures and conditions that cause these tiny life forms to multiply. MRI experiments could visualise these processes acting deep within porous media under extreme pressure and temperature conditions and provide clues about which exoplanets have the potential to host life or how early life developed on planet Earth.

As a second example, reactive transport processes are also important when a fluid moves through machinery and interacts with its structures. Saar says that experts in compressor and turbine development have already expressed their interest in using the novel MRI technique for their experiments. That very different branches of science and technology want to use the new technology is precisely how it should be. “The custom-made MRI device is much too expensive to sit idle,” he explains. “Ideally, it will be operated practically round the clock. We’d like researchers and companies from all over the world to test various hypotheses in it—including those that go far beyond the geosciences.”

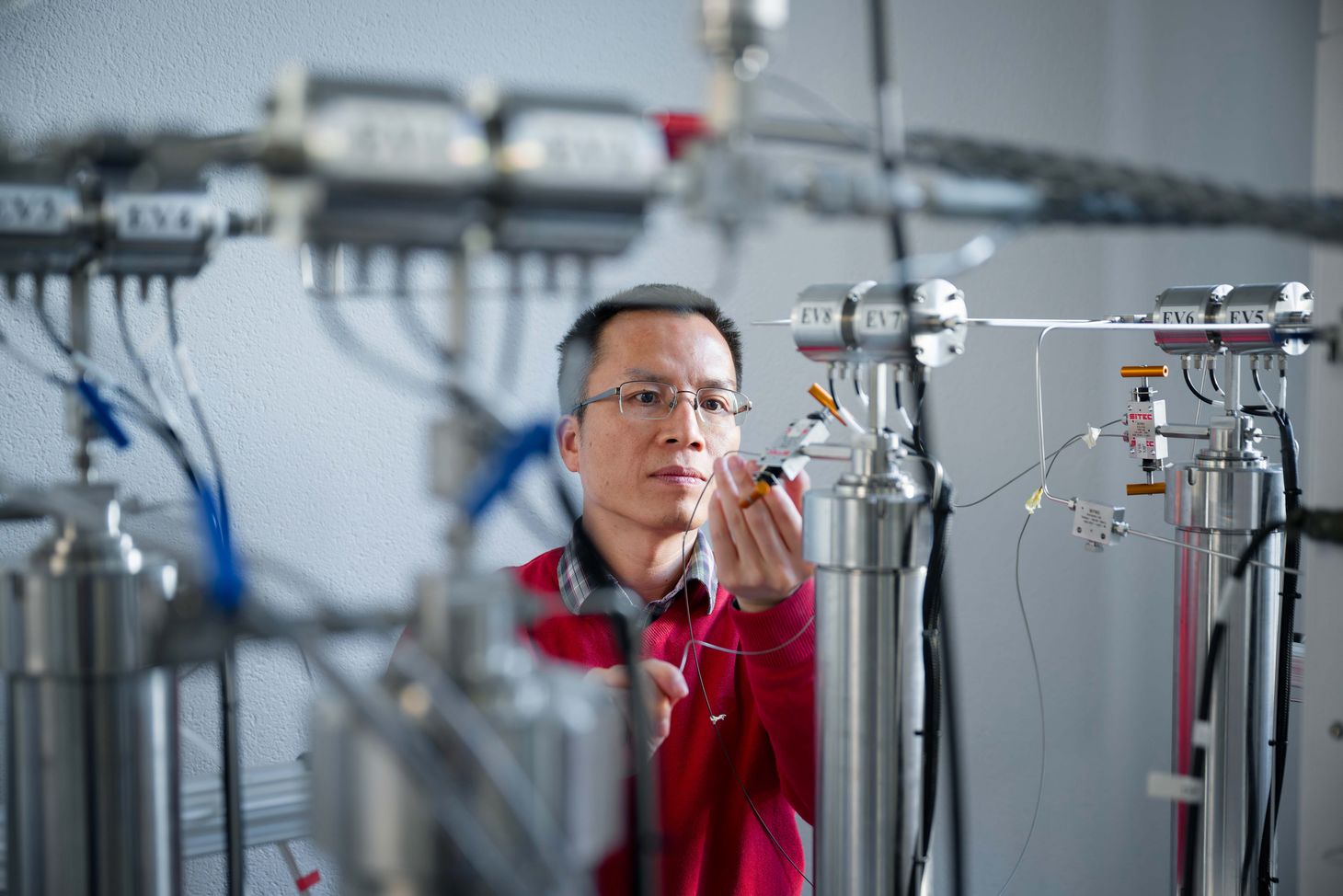

To ensure efficient use of the MRI, Saar has developed an innovative concept. Because reactive transport experiments can take weeks to conduct, every test will be set up and carried out on an experiment trolley. The individual experiments will be wheeled to the MRI unit only for the actual 3D measurements or visualisations by the MRI unit, with all tubes and cables remaining connected to the test object (see image). “It’s much like in a physics lecture, when experiments are prepared behind the scenes and then rolled out on stage for the demonstration,” Saar explains. This procedure has the advantage that the MRI isn’t occupied for weeks while an experiment is running—as would be the case when slow reaction times mean measurements are taken only in intervals of a few days.

Even such apparently minor details are of critical importance in the project. After all, the goal is for the new, one-of-a-kind MRI to generate as many ground-breaking findings as possible.

Facts and figures

Funding from the Werner Siemens Foundation

15 million Swiss francs over 10 years

Project duration

2024–2034

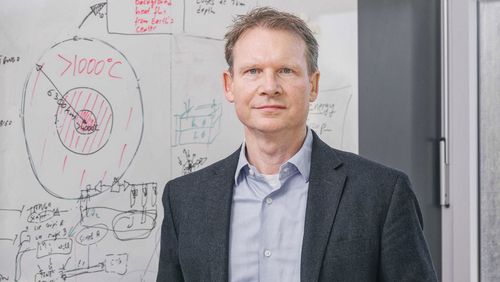

Project leader

Prof. Dr Martin Saar, Professor of Geothermal Energy and Geofluids, Department of Earth and Planetary Sciences, ETH Zurich