Thermoelectricity – from outer space to office space

Physicist Maria Ibáñez is pursuing an ambitious goal: over the course of the next eight years, she plans to either find or develop new thermoelectric materials that are able to convert temperature differences into electric power much more efficiently than currently known materials.

The thermoelectric effect has been known as a physical phenomenon for quite some time. It works according to the following principle: if one side of a material is warm and the other cold, electrons will collect on the cold side, creating electric voltage. If the material is then connected to a circuit, the electrons can flow—and the flow of electrons is, by definition, electricity. Although the energy, called thermopower, created from thermoelectric materials can be used to power devices such as electric light bulbs, the voltage is very low, measuring only a few microvolts per kelvin temperature difference. As such, the thermoelectric effect, even 200 years after German physicist Thomas Johann Seebeck first described it, is still not viable for large-scale power production. The thermoelectric materials used so far simply lack the required efficiency. To change this, Maria Ibáñez and her interdisciplinary team of researchers are seeking new thermoelectric materials that can generate maximum levels of electricity from minimal temperature differences. To do this, the team first connect molecular complexes and nanoparticles to form building blocks that can be used to construct novel thermoelectric materials; they then test the thermoelectric properties of the newly created materials.

From hot to cold

With thermoelectric materials, heat can theoretically be converted into electricity wherever and whenever temperature differences are present: car engines, windowpanes, water pipelines, the human body, laptops or charging devices. “If we had efficient and cost-effective thermoelectric materials, we could use all kinds of temperature gradients to generate electricity in many areas of life,” says Ibáñez. But for optimal effect, a different kind of thermoelectric material will most likely be required for each different application. On clothing, for instance, we would need a thermoelectric material that works best at room temperature; in a car engine, by contrast, the material would have to prove its mettle at temperatures of around 500 degrees Celsius. “We’re interested in all temperature ranges,” says Maria Ibáñez.

Reliable and maintenance-free

Wherever electricity flows, large quantities of energy are lost as heat—a familiar-enough phenomenon when we think of how our computers, smartphones and chargers heat up when we use them. Moreover, large quantities of energy are lost when electricity is generated: over 60 percent of all power generated in Europe seeps into the environment in the form of waste heat. “If we could find a material that captures this waste heat and, via thermoelectric generators, transforms it back into electricity, we could generate power from almost anything,” is how Ibáñez sees the potential of her research. “That’s our big dream—but it’s a little unrealistic. What’s more realistic is using thermoelectricity to power smaller electrical components like remote controls or temperature regulators.” In IT, for instance, thermoelectricity could be used to cool computers or other electronic devices. And Maria Ibáñez also sees potential applications in agriculture: farmers could use humidity sensors in the ground to know when a field requires irrigation. “The advantage of thermoelectricity is that it’s extremely reliable and safe to operate. You don’t need to charge anything, no sunlight or wind is required, there’s no maintenance—you need nothing other than a difference in temperature,” Ibáñez says and adds, “Although thermoelectric technologies are unable to deliver huge amounts of power, they can generate a constant flow of electricity—and that with absolutely no sound. What’s more, it’s ‘reversible’, meaning the selfsame device can be used to generate power and to cool.”

Thermoelectricity in outer space

Maria Ibáñez points to current applications in space travel for examples of how thermoelectricity has operated maintenance-free for many years. The space probes Voyager 1 and Voyager 2, which were launched in the mid-1970s and which have long since travelled beyond our solar system, continue to send data from their interstellar journey. The thermoelectric device used to generate power has been functioning for over 40 years, all with no maintenance or outside assistance.

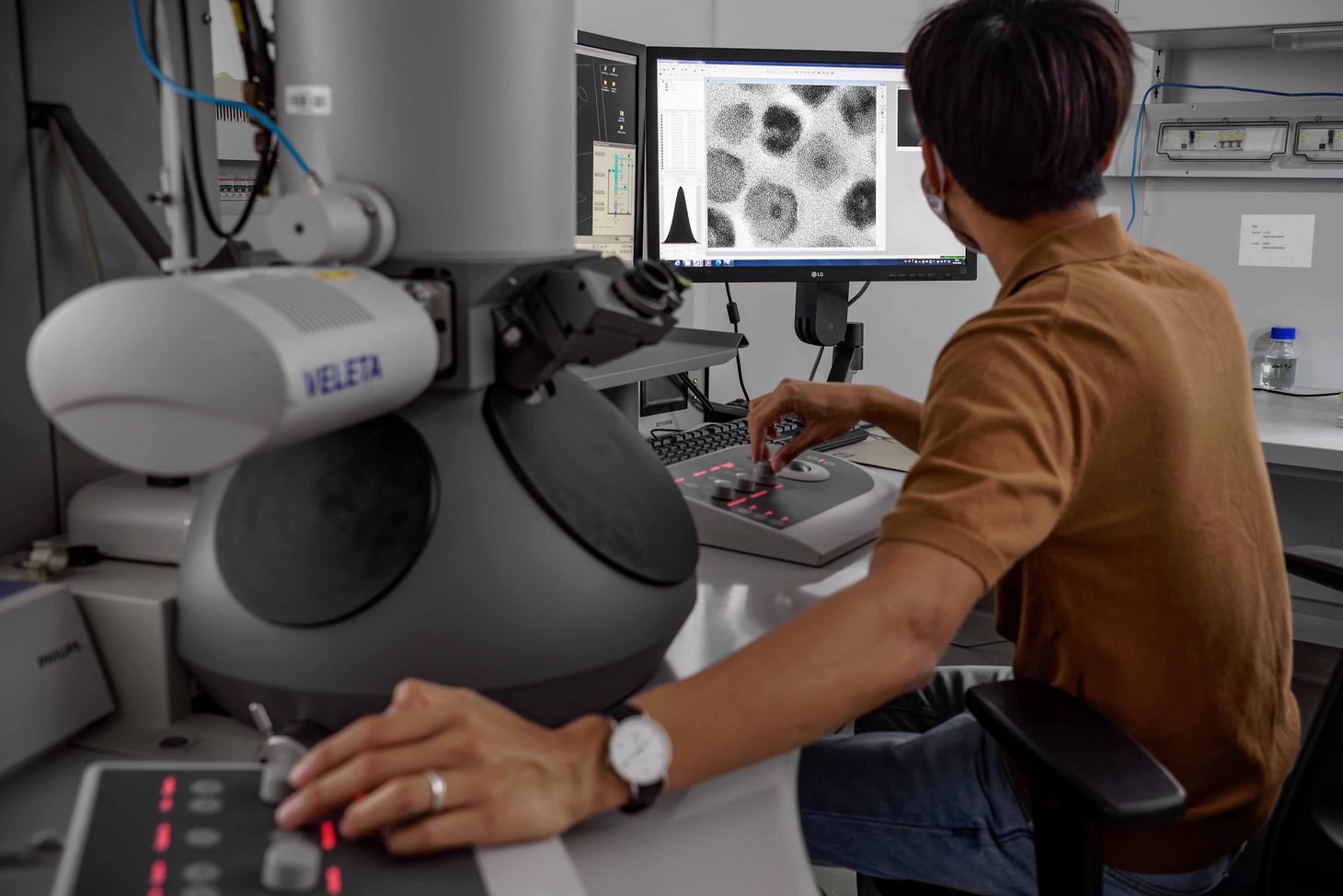

Novel nanomaterials

Ibáñez is manufacturing the new, optimised thermoelectric materials from precursor materials at the nanoscale. One nanometre is equal to one billionth of a metre. As such, nanoparticles are unimaginably tiny—“about as small as a millionth of a strand of hair”, is how Maria Ibáñez frames it. Nanoparticles occur naturally, for instance, after a volcano eruption or forest fires. For research, however, nanoparticles are created in the lab—with extraordinary precision and under highly controlled conditions. Ibáñez and her team synthesise the particles from metals or semiconductors, or combinations of both. Size, surface, composition and numerous other factors can be modified, resulting in an entirely new kind of nanoparticle. “Their chemical and physical properties—for example, their chemical reactivity, electrical conductivity or their thermodynamic properties—change,” says Ibáñez. Nanoparticles made in the lab can be formed into larger crystals that often have entirely different properties than the original particles. “We use these nanocrystals as building blocks, like Lego, that can be combined and varied in innumerable ways,” says Ibáñez. The team are employing a range of chemical and physical processes to gradually make their way towards new materials with the best-possible thermoelectric properties.

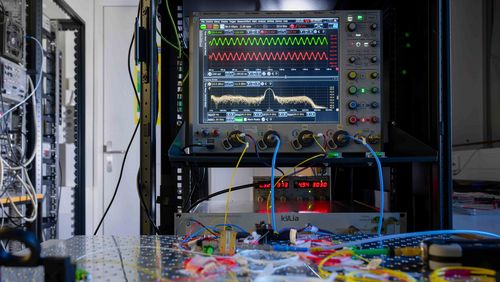

High-throughput analyses

What properties do these lab-made nanocrystals have? Can they be used as a thermoelectric material? Do they function better at high or low temperatures? The team is scrutinising the nanomaterials to achieve a precise categorisation of their properties. Until now, these analyses have been conducted by hand in the lab, a painstaking, time-consuming undertaking. “To speed up the process, we’re now developing a high-throughput testing infrastructure,” says Ibáñez. In the new lab, which will be ready to use in 2021, Ibáñez’s research group will conduct what is called high-throughput experimentation (HTE). As such, they will belong to a small, select number of research groups in the world that use computer-assisted high-throughput technologies to identify high-efficiency thermoelectric materials. With HTE, the researchers can simultaneously test large amounts of starting material for different parameters. “This will markedly accelerate the production of a very wide range of nanomaterials in different states,” says Ibáñez. In the coming six months, she will be recruiting an engineer with whom she can design the HTE system. Further evidence that Maria Ibáñez’s research, as is standard at IST Austria, thrives in an interdisciplinary setting.

Text: Brigitt Blöchlinger

Photos: Felix Wey