A game-changing decision

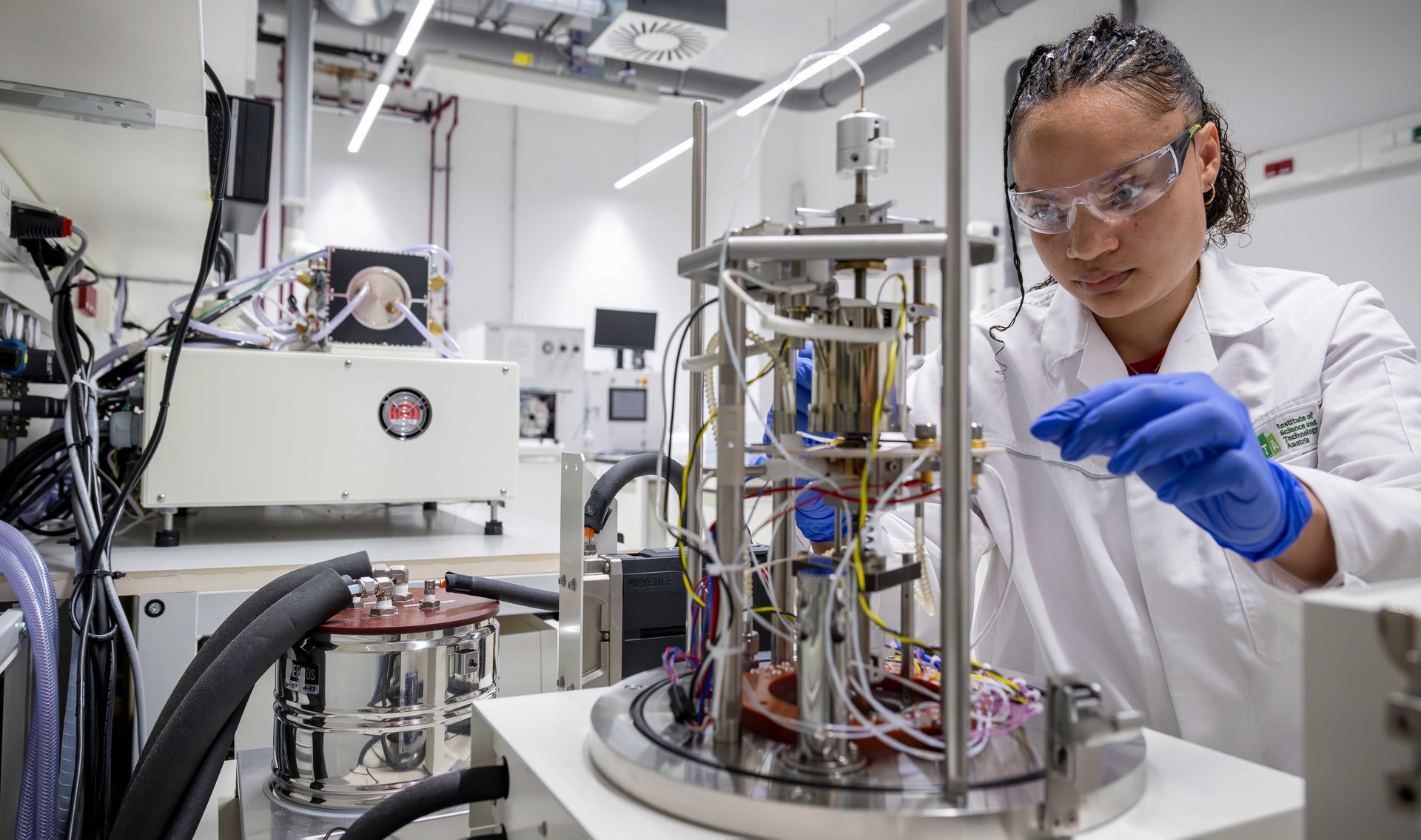

Maria Ibáñez and her team at ISTA are making steady progress in their search for materials that can efficiently convert temperature differences into electricity. They also reached a major decision concerning the high-throughput equipment they’ve been planning: a specialised firm will now build parts of the system.

Fabricating thermoelectric materials is a complex and time-consuming process. The most minuscule changes are what determines whether or not a material has the right properties, and when researchers have to produce every new potential material by hand in their lab and then test it individually, progress is painfully slow. That’s why physicist Maria Ibáñez at the Werner Siemens Thermoelectric Laboratory at the Institute of Science and Technology Austria (ISTA) has chosen a different strategy: she wants to use a high-throughput system that can fabricate and test a large number of materials in a highly automated process.

Ibáñez had originally planned on developing and constructing the custom-made, high-performance unit in her own lab. “But that turned out very challenging,” she says. As often in research, one must be creative in the face of the unexpected and seek a different approach. In the case of Ibáñez, the solution lay in Switzerland.

Specialised Swiss firm

Her search led her to Switzerland, where she found a company specialised in the construction of these kinds of highly complex devices. “I had various conversations with the people in charge there, we developed the platform concept together—and the agreement is that the firm will build the platform in the course of 2025,” Ibáñez says. In the end, she’s very pleased with her decision: “In some way, it was a step backwards, but I’m convinced the project is now headed in the right direction.”

Parallel to this work, Maria Ibáñez and her team have also made major strides in researching and fabricating thermoelectric materials in recent months. For example, they conducted a study that demonstrated the production steps leading to differences in a material’s purity—and hence differences in its thermoelectric performance. “This knowledge is crucial,” Ibáñez explains. “Without it, we’d otherwise be doing guesswork when we analyse various parameters in the high-throughput device. In addition, the descriptions of these steps in some scientific publications aren’t detailed enough, which means the results aren’t reproducible.”

Pellets from 3D printers

In another notable publication, the researchers worked with silver selenide (Ag2Se) as an example material to demonstrate a production pathway that can be used to precisely control the microstructure of a composite material. They devised a three-step synthesis strategy: producing silver-selenide particles in a solution, cleaning and drying the particles into a powder, and then solidifying the resulting powder into a type of pellet.

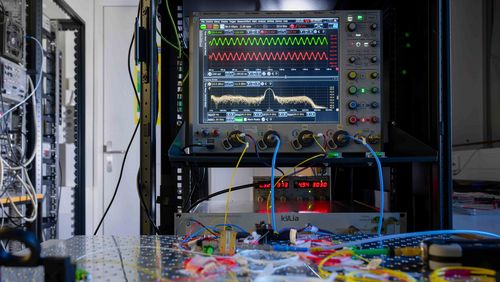

In the high-throughput system, this solidification process is very time-consuming, which is why the ISTA thermoelectric team decided to modify a 3D printer, enabling it to print the pellets that the researchers then analyse for their thermoelectric properties. “The 3D printer is extremely fast, and we’re saving material and energy by using it,” Maria Ibáñez says. “Right now, we’re using this method to fabricate materials that achieve record performance at room temperature.”

More robust, less fuss

This new development also has consequences for the planned construction of the high-throughput infrastructure. The team’s original idea was to convert their powder into a type of ink that could be sprayed onto foils. “But it takes a lot of time to find the right conditions to manufacture good layers for each material—which is what enables us to characterise the material properties,” Maria Ibáñez explains. And so the team opted to develop inks for 3D printing instead. “Another advantage is that analysing the 3D pellets is both easier and less error-prone.”

In sum, it seems the outlook is rosy for the thermoelectric project, and that the researchers will be able to fabricate and analyse a whole host of promising materials in future—materials that will lend new impetus to power generation and temperature control.