Climate-friendly reinforced concrete

Concrete is the most widely used building material in the world. However, conventional production methods release massive amounts of carbon dioxide into the atmosphere. Civil engineer Ueli Angst from ETH Zurich believes it’s time for this to change. In his work, he’s challenging long-held beliefs surrounding corrosion protection in rebar—and laying the foundation for more climate-friendly concrete structures.

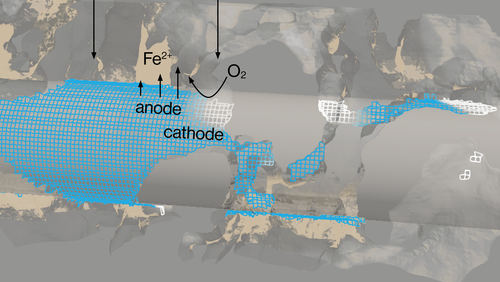

Worldwide, the manufacture of concrete is responsible for emitting three times more carbon dioxide than air traffic. One of the main reasons for this dubious distinction are the high alkalinity levels in concrete—which are currently believed to be the only way to prevent reinforcing steel from corroding. Civil engineer Ueli Angst from ETH Zurich, however, has clear indications that this view is outdated. And he has plans to develop more climate-friendly alternatives.

To produce concrete, water and aggregate materials such as sand and gravel are admixed to the binder material cement—the component in concrete that’s most harmful to the environment. Cement is made with limestone and raw materials like clay that are heated in a furnace, where the high temperatures break the limestone down into calcium oxide and the greenhouse gas CO2. The highly alkaline calcium oxide causes a layer to form on the surface of the steel, preventing the iron molecules in the steel from separating—and protecting reinforced concrete from corrosion.

Over time, the conviction that high alkalinity is the basic requirement for corrosion-resistant concrete became widely accepted both in the world of research and in the construction industry. Now, however, Ueli Angst and his team at the ETH Zurich Department of Civil, Environmental and Geomatic Engineering are calling this doctrine into question. Indeed, they’ve already demonstrated that concrete structures can be resistant to corrosion even after they’ve lost their alkalinity if additional measures are taken—for example, if a structure is protected from moisture. With financing from the Werner Siemens Foundation, the researchers will now conduct a comprehensive investigation into the complex corrosion processes in different types of concrete under various climatic conditions.

Their aim is to initiate no less than a paradigm shift in the building industry and to generate new ideas for corrosion protection. In future, the team believe that the type of concrete used could be adapted to specific weather conditions, that customised coatings could serve to protect concrete and steel from moisture, or that novel components could be added to a mixture to equalise moisture levels in concrete. All these factors will help put an end to the era of building with environmentally harmful concrete and pave the way for new, ecological kinds of concrete.

Facts and figures

Project leader

Prof. Ueli Angst, ETH Zurich, Department of Civil, Environmental and Geomatic Engineering

Project

Ueli Angst, civil engineer and professor at ETH Zurich, is seeking alternative ways to manufacture highly alkaline concrete, which causes excessive greenhouse gas emissions. His aim is to demonstrate that reinforced structures made of less alkaline concrete can still be resistant to corrosion.

Support

The Werner Siemens Foundation has awarded the project a ten-year grant.

Funding from the Werner Siemens Foundation

10 million Swiss francs

Project duration

2024–2034

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/d/f/csm_01_WSS_News_Beton_90d32370a8.jpg)