Seeing inside rock layers

The Werner Siemens Foundation has supported Professor Martin Saar’s geothermal and geofluid research for the past ten years. During this time, several innovative developments have resulted in collaborations with industrial partners. Now, in a follow-up project funded by WSS, Saar is planning to study simulated geological formations in his ETH Zurich lab.

Researchers who want to study the Earth’s interior need to get a little creative. After all, the Earth’s crust is even harder to access than the deep sea or outer space, and diving into it—or flying there in a spaceship—are hardly viable options. That’s why geophysicists like Martin Saar, Werner Siemens Foundation Endowed Chair of Geothermal Energy and Geofluids (GEG) at ETH Zurich, need to take recourse to other, often indirect and complex means in their endeavours to learn more about subsurface conditions and processes.

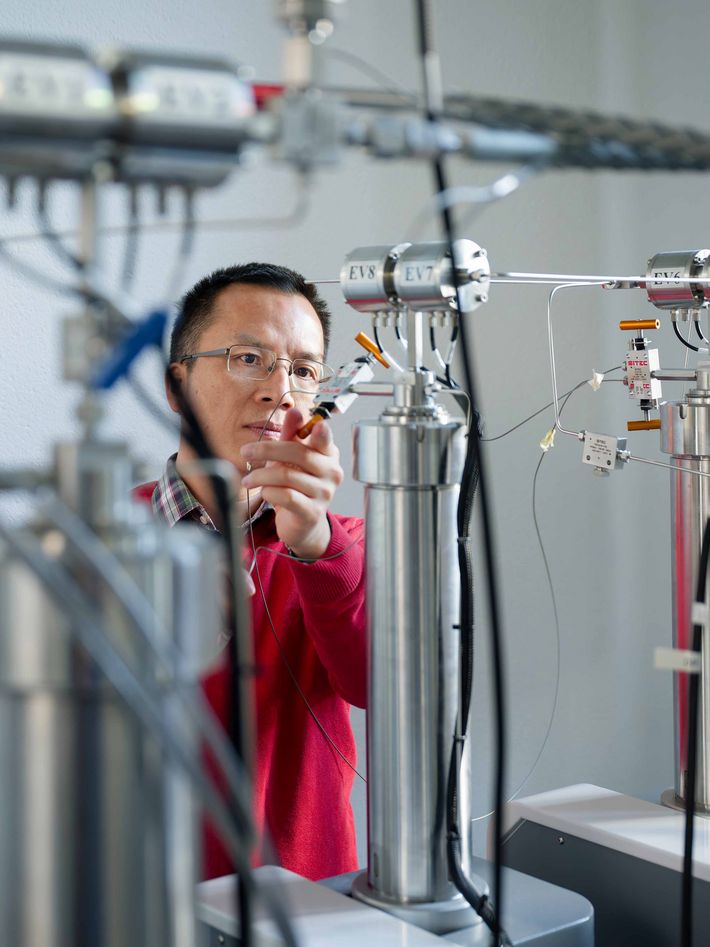

A tour of Saar’s labs offers insight into this fascinating work. Several small cylindrical pieces of granite of roughly five centimetres in length are resting on top of a lab table. The researchers use these miniature specimens, called granite cores, to learn more about the processes occurring in deep rock layers. Martin Saar points to a nearby unit with various hoses and a steel cylinder. “We use it to heat the granite cores to up to two hundred degrees Celsius and expose them to pore water pressures of up to one thousand bar”—an environment that corresponds to the conditions found at a subsurface depth of roughly ten kilometres. The researchers inject fluids (liquids or gases) into the tiny pores, cracks or fissures in the granite core, and then measure flow velocities and any changes in the rock.

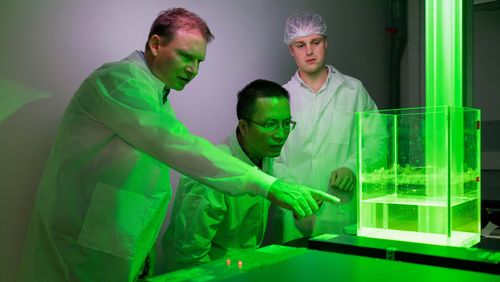

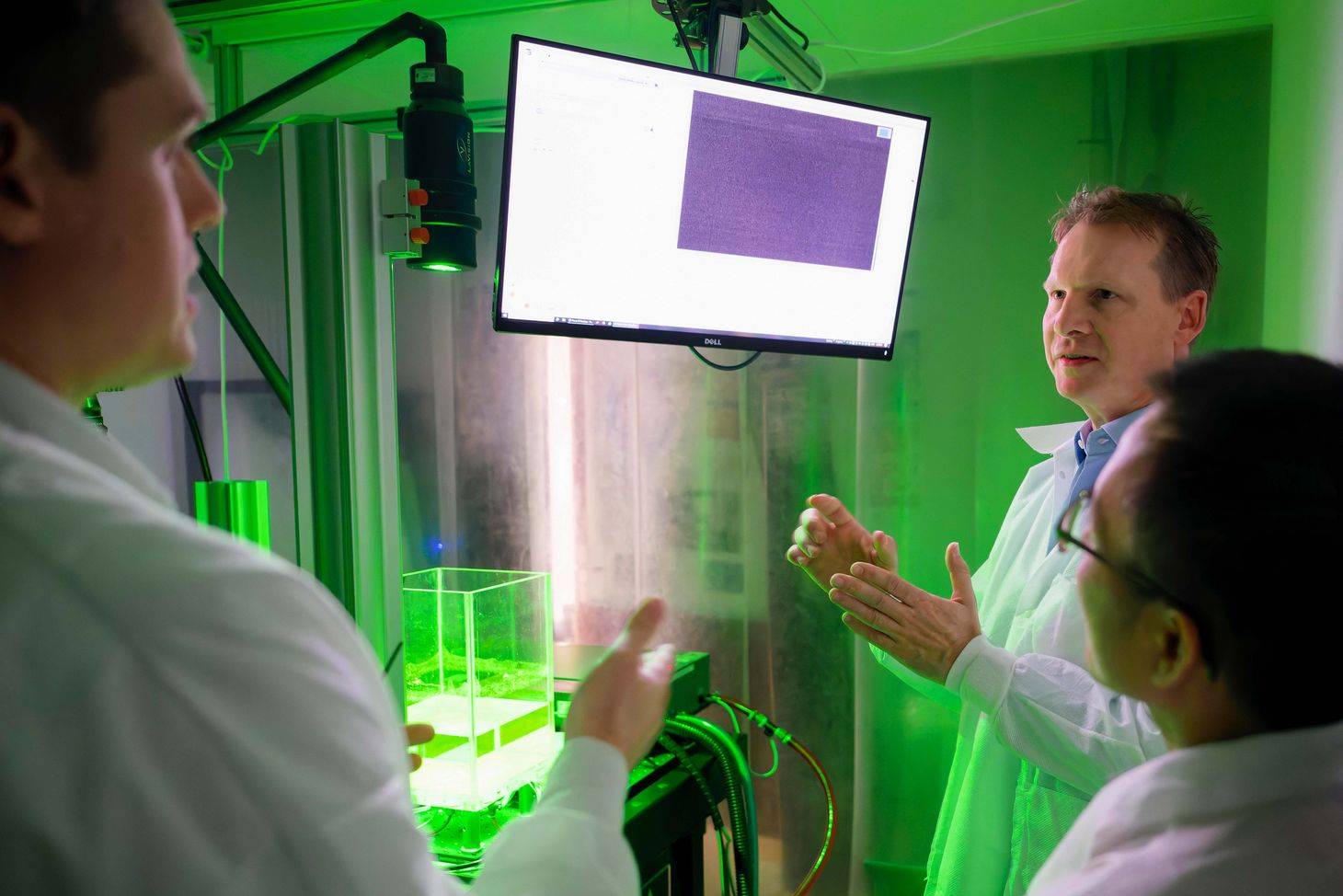

The 3D printers located near the windows in the lab represent another way to conduct measurements. The researchers use the printers to fabricate plastic elements replete with hairline cracks to simulate joints in the rock layers. They then introduce a fluid enriched with fluorescent particles into the elements and observe flow behaviours under various conditions.

Consultancy for geothermal projects

Some of the experiments can be classified as basic research, while others focus on real-world application. This is because Martin Saar’s GEG group has set itself the goal of advancing deep geothermal energy, which has the potential to supply the world’s population with sustainable energy sourced from the Earth’s interior. However, tapping into geothermal reservoirs remains challenging. For one, the cost of drilling is exorbitant, as the energy is located several kilometres below the Earth’s surface. And because the underground is so difficult to survey, trial drilling conducted by prospectors often hit unsuitable rock layers.

Despite—or possibly because of—the challenges, Martin Saar has observed a growing interest in scientific consulting in both the geothermal industry and the political sphere. In response to this demand, he’s currently setting up a consortium for geothermal energy in Switzerland. The project will be led by Dieter Werthmüller, an experienced geophysicist whom Saar recently invited to Zurich. With the support of private companies and governmental offices, the consortium aims to lay the scientific foundations for geothermal projects in Switzerland—by mapping the geology of the underground, for example.

The consortium will also advise on specific projects. Saar says that several earlier projects in Switzerland have failed simply because the right rock layers couldn’t be found. “Our project will help ensure that drilling in future geothermal projects will no longer be hit and miss.”

To deliver on all these promises, the researchers must leave the lab and conduct field studies. Saar’s GEG group is specialised in magnetotellurics, a key geophysical method used to determine the three-dimensional electrical conductivity of the subsurface by measuring secondary electromagnetic fields on the Earth’s surface that are generated underground by the solar wind. Subsurface electrical conductivity is contingent on how permeable the subsurface is for fluids. “Magnetotellurics can aid us in locating potential sites for hydrothermal geothermal power plants and geological CO2 storage, because a permeable reservoir deep in the subsurface is a prerequisite for these processes,” Martin Saar explains, adding that project leader Dieter Werthmüller’s expertise in the field of magnetotellurics will give this area of research in his group an even greater boost.

A consortium and a large-scale project

The two most common types of deep geothermal energy production are hydrothermal and petrothermal geothermal energy. The former capitalises on permeable rock layers in which water circulates naturally, generally at depths of up to five thousand metres. The latter, by contrast, taps into the earth’s heat from compact, impermeable rock layers at depths of five to seven thousand metres. Aside from these processes, there are other, newer methods—to which Saar’s research group has made major contributions. For instance, fifteen years ago, Saar co-invented the CPG method (CO2 Plume Geothermal), which functions by injecting CO2 into a suitable reservoir located 2.5 to 5 kilometres below the ground, where the greenhouse gas heats up to at least 100 degrees Celsius.

This heat can be exploited via a circuit: the heated CO2 is brought to the land surface, where it’s used in turbines to generate electricity—and then, after cooling, is channelled back into the underground storage facility so that the CO2 injected at the start is permanently stored deep in the subsurface. Because CO2 is less viscous than water and expands much more when heated, it has a higher heat production rate, theoretically enabling more economical extraction of geothermal energy, and even the production of electricity, in less permeable rock layers at relatively low subsurface temperatures.

Two years ago, Martin Saar established the CPG Consortium, which is now conducting a feasibility study of the approach. The consortium is led by Jasper de Reus from Saar’s GEG group, and its members include major companies like Shell, Petrobras, Holcim and Ad Terra Energy. And, as Saar relates, the Swiss Federal Office of Energy has recently become a sponsor. The initial phase is dedicated to gathering information about reservoirs across the globe to determine their potential for use. Following additional investigations, a large-scale demonstration project will be carried out.

Another more recently developed technology is called AGS (Advanced Geothermal Systems), which can be described as a type of heat exchanger that penetrates deep into the subsurface. A fluid circulates in a closed-loop circuit where it’s heated by subsurface rocks. Saar and his team are testing the potential of this method in AEGIS-CH, a large-scale project financed by the Swiss Innovation Agency (innosuisse) in its flagship programme. In AGS, two boreholes are joined together by several U-shaped loops at a depth of five to ten kilometres below the Earth’s surface; heat is then extracted from the rock using CO2 as a circulation fluid. It’s believed this kind of power plant could generate enough energy for five hundred to one thousand people—and it could be built in many different sites, as no particular geological conditions are required.

New drilling methods

The cost of drilling in the subsurface is one of the biggest problems encountered in deep geothermal projects. “You could say we’re still using Stone Age methods to drill—the technology is based on abrasion,” Saar says. Any geothermal undertaking that relies on conventional methods to break through kilometres of underground rock must reserve a good deal of time—and money—as the hard terrain takes a toll on the drill bits. In the interest of finding a better way, one of Saar’s research priorities in the AEGIS-CH project is a method he helped develop: Plasma Pulse Geo Drilling (PPGD). Rather than mechan-ically breaking up the rock, PPGD functions with a type of electric shock: electric pulses blast through the rock, generating a plasma arc that fractures the rock from the inside out, much like scooping out ice cream. The technology consumes only around a quarter of the energy of conventional drilling methods, making it much more cost-effective.

Saar also has plans to research and further innovate another novel drilling method; this endeavour will be in collaboration with his ETH Zurich colleague Professor Alexander Barnes and Jasmin Schönzart, a postdoc in his GEG group. “Here, it’s all about using microwaves,” Saar explains. Specifically, a gyrotron—an extremely powerful microwave generator employed in nuclear fusion reactors—will send compact, high-power waves into the subsurface rock. “The temperatures in the rock layers rise to several thousand degrees Celsius, causing the rock to vaporise,” Saar says.

Renewed funding

Saar has been able to pursue his many projects thanks in part to a ten-year grant from the Werner Siemens Foundation. Although the funding is set to expire at the end of 2024, Saar will be able to continue his pioneering research, as WSS has awarded him a new grant of fifteen million Swiss francs for the next ten years. With its unique, cutting-edge approach, the project has the potential to generate entirely new insights into the complex geological processes in the Earth’s interior.

To explain this new line of research, Saar offers a tour of a second lab, which houses the group’s inhouse computer tomography (CT) scanner used for conducting so-called reactive transport experiments—studying the chemical interactions between porous rock and the medium flowing through it. Rock samples like the granite cores are placed in the CT scanner, where they’re exposed to geothermal pressures and temperatures, and a fluid is injected. The researchers can then observe in real time where the rock begins to weather, where minerals precipitate and how energy flow paths are blocked as a result.

The method has various applications and is used in the group led by senior researcher Maren Brehme to investigate how flow pathways affect operations at geothermal power plants over the course of time. Brehme is specialised in identifying—and solving—such problems. Saar relates how, in Indonesia, the group was able to clearly demonstrate how the production rate of geothermal plants can be increased.

However, CT scanners have one disadvantage: their functionality is based on X-rays, which are attenuated to varying degrees depending on the density of a structure. “That’s why we can primarily observe how the rock changes,” explains Saar. “Differences between gases and aqueous solutions, or their flow behavior, are hardly visible to us.”

Custom-made MRI

During the next WSS funding period, the researchers are aiming to change this—with a custom-made magnetic resonance imaging (MRI) device that is likely the only one of its kind in the world. Unlike CT scanners, MRIs can render different fluid types visible. Put simply, the MRI excites the nuclei in certain atoms via a magnetic field, causing them to vibrate; the signals generated by these vibrations are processed, enabling distinctions to be made between different kinds of materials.

Most commonly, MRIs target hydrogen atoms (H-1), but some models can also measure several different elements such as carbon, fluorine, sodium and xenon isotopes. Saar has plans to design a multi-nuclide MRI device, which will be constructed by an external company. “The individual components we need have already been developed, but not yet in the combination necessary for our purposes,” he explains.

He estimates it will take about two years to plan, procure and construct the device. By then, the second key component for the MRI experiments should also be ready: a 3D printer capable of producing ceramic replicas of rock layers—including underground deposits, reservoirs, faults and boreholes. The geological formations in miniature will be roughly the size of a brick, yet still contain all important geological features, thanks to modern 3D printing technology that can produce ultra-thin layers measuring no more than a hundredth of a millimetre.

Methane production with microbes

Saar will also use his new MRI to explore yet another idea: underground methane production. In his vision, sustainably produced “green” hydrogen and CO2 are introduced into the subsurface together with microorganisms capable of utilising the Earth’s heat to transform the hydrogen and CO2 molecules—in a carbon-neutral process—into methane. When needed, the methane generated underground is then conveyed back to the ground surface and used as an energy resource in existing facilities.

Conducting “methanogenesis” is, however, a highly complex undertaking, especially in the deep subsurface, which is why lab experiments must first be carried out. It’s precisely for these kinds of simulations that the new MRI will be ideal, as Saar explains: “It will enable us to observe where the CO2, hydrogen, microbes and methane produced go and where they accumulate. We can use this information to optimise the placement of injection and production wells.”

The data gathered in these experiments will be incorporated into computer simulations, yet another indispensable tool in the GEG lab. Xiang-Zhao Kong, senior researcher in the team, is a specialist in the field. For his work, the data delivered by the MRI scans—3D temperature fields, pressure fields and velocity vectors of the various fluids and microbes—are invaluable.

Interdisciplinary interest

It should be noted that the significance of the new MRI system is even greater than Saar’s groundbreaking geothermal experiments. One cross-disciplinary application is a planned collaboration with the ETH Zurich Centre for Origin and Prevalence (COPL) led by astronomer and Nobel laureate Didier Queloz. Researchers at COPL are interested in understanding where and how carbon and microbes accumulate in rock layers and how the latter multiply there; these environments can be simulated and observed in the novel MRI to uncover clues about the origin of life on Earth or other planets.

Last, but not least, specialists in the field of compressor and turbine development have expressed their interest in using the MRI for their experiments. Saar says that’s exactly how it should be: “This kind of specialised, custom-made equipment is much too expensive to sit idle. It should be used practically round the clock.” One way or another, Martin Saar is certain the investment will pay off—also for disciplines that go far beyond the geosciences.