An expert all-around

At Saarland University Medical Center, a team of specialists from the fields of medicine, engineering and computer science are developing intelligent implants that will enable complex bone fractures to heal with fewer complications. Werner Siemens Foundation Endowed Chair Bergita Ganse has recently been appointed coordinator of the broad-ranging project; her aim is to exploit synergies between the diverse disciplines—while contributing knowledge from outer space.

In the earth’s orbit, everything is as light as a feather—astronauts can push off with a mere finger and glide effortlessly across the space station. Yet as heavenly as zero gravity may initially feel, in time it presents problems. “We have to work our muscles and bones, otherwise they start to deteriorate,” says trauma surgeon Bergita Ganse, who has spent many years studying solutions to the issue. Her research has helped the European Space Agency (ESA) and and the National Aeronautics and Space Administration (NASA) to further develop their training methods for astronauts—through the use of special weight training equipment, treadmills and exercise bikes, for example.

High ambitions

These days, Bergita Ganse’s research setting is firmly earth-bound, and in March of 2021, she was appointed Werner Siemens Foundation Endowed Chair at Saarland University in Homburg, Germany. In her new role as coordinator of a team of medical, engineering and computer science experts, she wants to help revolutionise the treatment of fractured bones through the use of smart implants. The implants of the future will not only stabilise bones, but also independently detect and counteract incorrect weight bearing—what Ganse calls an ambitious but attainable goal. Indeed, she is not shy of aiming high herself: a hobby athlete, Ganse formerly competed at the European Masters Championships in the Throws Pentathlon event.

Innovation through collaboration

With her background, Ganse believes she is optimally positioned to mediate between the various disciplines. In her most recent post, she received a research grant to work at the Research Centre for Musculoskeletal Science and Sports Medicine at Manchester Metropolitan University in England. Prior to that, she conducted research into implants and other subjects in Aachen, earning her habilitation (professorial qualification) in experimental orthopaedic surgery. Ganse is also very familiar with the workings of a medical clinic, having completed her Medical Specialist Qualification for orthopaedics and trauma surgery as well as for physiology at Charité in Berlin, at the German Aerospace Center (DLR) and at the university hospitals in Cologne and Aachen. During her time at DLR and in Manchester, she practically “lived among engineers”, as she tells it; nor is she a stranger to the questions explored by computer scientists, with whom she has collaborated in various research projects. “My goal is to unite these diverse worlds,” says Ganse, “because innovation is often dependent on specialists from various disciplines passing the ball to each other.”

Material that moves

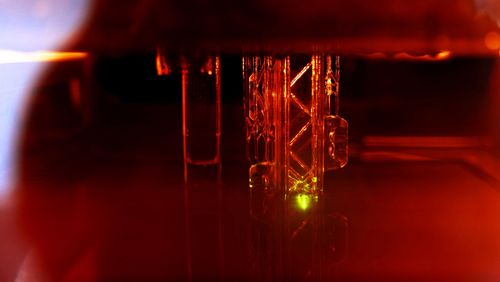

In 2021, engineers at the Center for Mechatronics and Automation Technology in Saarbrücken achieved an initial breakthrough: they succeeded in building a so-called demonstrator that incorporates an actuator component—an implant made of metal and synthetic materials that can contract and expand. The “shape memory” properties of the materials is what makes this possible: the nitinol wires shorten when they are warmed by an electrical current and “relax” again in the absence of voltage, thereby mechanically stimulating the fractured bone. The researchers have now filed the first patents for their prototype construction.

Although the prototype features an actuator component, it still lacks adequate sensory characteristics, let alone intelligent properties. Indeed, before the implant is ready for use, it must be able to precisely measure the forces acting on the bone and process this information, which the prototype cannot yet do. Another challenge is the power supply—both implantable, fully autonomous solutions and inductive charging could be used. Moreover, the implant’s compatibility with the human body must be ensured. By using currently known implantable materials and encapsulations, Ganse is certain that the goal is fundamentally realistic.

How much weight bearing is ideal?

The technology is already highly advanced. But without medical research, even the most intelligent implants are not fit for purpose. Before smart implants can actually aid the healing of fractured bones, two central questions must be answered: Which forces and pressures act on bones when walking and performing everyday activities? And, what is the ideal weight to put on a healing fracture? The medical specialists in the group of project leader Professor Tim Pohlemann are currently collecting the necessary background data by using sensors in shoe soles. And identifying ideal weight bearing is also a matter with which new Werner Siemens Foundation Endowed Chair Bergita Ganse is well acquainted: “The issues to address are, in principle, similar to those in space research.”

Text: Adrian Ritter

Photos: Oliver Lang