Monitored healing

When treating fractured bones, doctors generally use standard implants. A plate is screwed into the bone to stabilise the fracture—regardless of whether the bone was twisted, bent or crushed. In 10 percent of cases, however, complications arise. To improve treatment, an interdisciplinary team at the Saarland University Medical Center is developing intelligent implants that not only stabilise the fractured bone but also detect and counteract incorrect weight bearing in individual patients.

The treatment of bone fractures has seen two major revolutions: in the 1960s, physicians began stabilising fractures with plates, relieving patients from long periods in heavy casts. The new procedure shortened rehabilitation time, prevented bone malalignment and allowed for greater mobility during the healing process. For many years, however, the only plates available were the few standardised models that had been developed to treat skiing injuries, and these were often unsuitable for the complex spiral and multiple fractures that commonly occur in traffic accidents. The second revolution, then, was the development of numerous new implants beginning in the 1980s. A team of physicians at the Saarland University Medical Center are now aiming to start a third revolution: together with partners from the fields of applied mechanics, mechatronics and computer science, they want to develop smart implants that can monitor the healing of fractures and help to remedy incorrect weight bearing—autonomously, with no action required from either doctor or patient.

Personalised fracture treatment

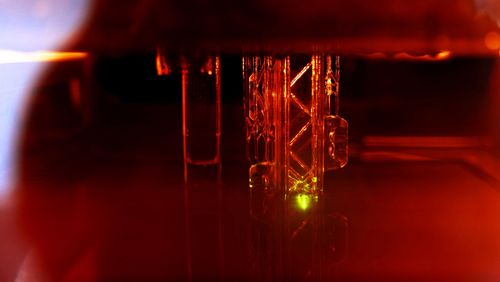

Today, complications arise in around 10 percent of bone fractures; affected patients suffer pain and require further treatment. Aside from the personal trauma, this also places a burden on society, as the additional therapy increases healthcare costs and patients are unable to work. “Innovative technologies could make bone fracture treatment safer, more individual and more cost-effective,” says Dr Marcel Orth, who leads the project at the Saarland University Medical Center. Adapting standard plates currently used to stabilise bone fractures is one approach to developing the novel implants; using external fixations, which have the advantage of protecting sensitive soft tissue, is another option. The idea is to apply a layer of “intelligent” materials—materials with sensoric and actuator (self-acting) characteristics (see interview pages 48 to 49)—to the standard plate or external fixation. Translating these new technologies from materials science to medical applications is the focus of the mechatronics engineers at the Center for Mechatronics and Automation Technology.

Intelligent implants

The aim is to create intelligent implants that can detect and respond to incorrect weight bearing on a fractured bone. For instance, if too much pressure or weight is placed on a fracture, the implant stiffens, relieving strain on the bone. By contrast, if a patient is too sedentary, the implant changes its shape and becomes more flexible, increasing the pressure on the bone. The implant can be monitored by an external device, such as a computer or smartphone, and is removed when healing is complete. The team plan to manufacture the components in a variety of shapes and sizes that can be combined to best treat the individual fracture. An additional benefit is that post-operative care is simplified. But before they can design intelligent implants that aid healing processes, the researchers must identify which conditions are conducive to healing and which factors cause complications. “Today, no one knows exactly why complications arise,” says Professor Tim Pohlemann, director of the Department of Trauma, Hand and Reconstructive Surgery, at the Saarland University Medical Center. In current practice, patients receive instructions solely on how much weight they should put on the bone. “After that, physicians can only cross their fingers and hope,” says Pohlemann. Little is known about the effect of weight bearing on healing; moreover, findings from preliminary studies suggest that patients rarely follow the instructions of the physician. “We assume that in their day-to-day lives, patients have difficulty in putting the right amount of weight—for instance, half their body weight—on the bone,” explains Pohlemann.

Understanding the healing process

One of the most important and challenging steps in the project is gaining a clear understanding of the healing process, and the first studies are already in progress. Test persons with a lower-leg fracture wear an intelligent insole in their shoe; the insole has 16 pressure sensors that record 82 parameters per step taken, enabling the researchers to identify the forces acting on an affected bone. Using these data, experts from the Professorship for Engineering Mechanics at Saarland University conduct simulations and experiments to determine exactly what happens to bones when they are exposed to everyday pressure and strain. The researchers plan to use artificial intelligence (machine learning) to distinguish between behaviours that promote healing and behaviours that tend to result in complications. Based on the test data, specialists at the German Research Center for Artificial Intelligence are developing algorithms that precisely predict which conditions are most likely to promote healing. To this end, the computer scientists define limit values for diverse parameters such as physical stress or strain; they also employ imaging techniques to enable healing prognoses on the basis of pictures. The project team is aiming to build a prototype of an intelligent implant and to complete initial testing on animals by 2025. Nevertheless, it will probably take another two decades before the new technology can be used to treat fractures in humans, as approval procedures are very complex. But project leader Marcel Orth remains optimistic: “Smart applications are already standard in a variety of areas, such as automobile technology. There’s no reason why innovations from materials science can’t be of great benefit in medicine, too.”

Text: Andres Eberhard

Fotos: Oliver Lang